Overview of Ion Beam and Plasma Processing Technologies

scia Systems offers a variety of ion beam and plasma processes for etching, coating, and cleaning of substrates. Due to their characteristic properties each technology has both advantages and disadvantages for specific applications. We will be pleased to help you find the right process for your application. Our technology portfolio includes the following processes:

ION BEAM ETCHING (IBE) / ION BEAM MILLING (IBM)

Ion beam milling uses a broad beam of positive charged ions, e.g. Ar+, to physically etch material from the wafer substrate by ion bombardment. The beam with a typical diameter larger than the substrate size ensures a sufficient removal uniformity and throughput. During the milling process the wafer substrate could rotate for best uniformity.

Related Systems

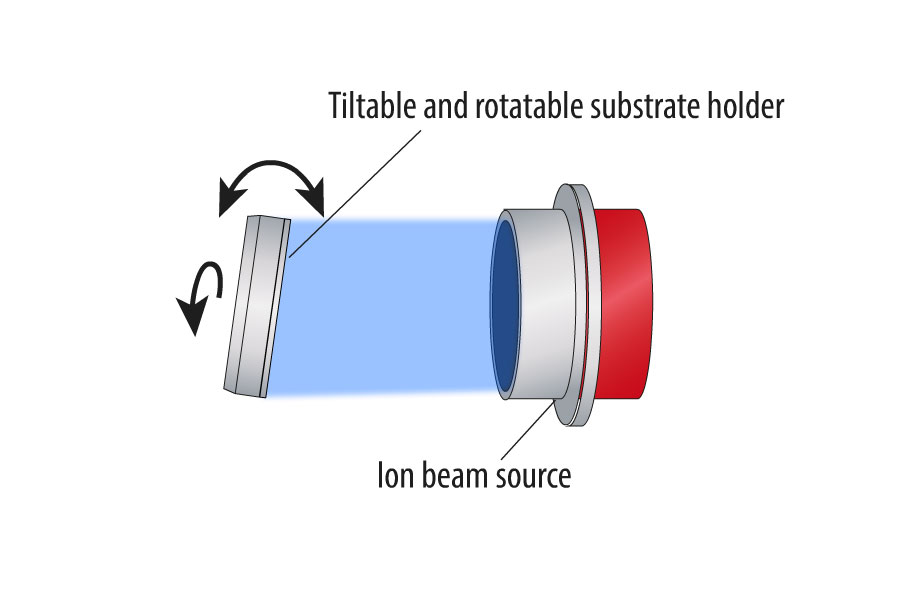

REACTIVE ION BEAM ETCHING (RIBE)

The reactive ion beam etching uses the technology of ion beam milling or ion beam trimming and adds additional reactive gases into the ion beam source. The plasma activation of the reactive gases leads to a chemical and physical etching of the substrate material, which helps to increase throughput, material selectivity, and trench angles of patterned surfaces.

Related Systems

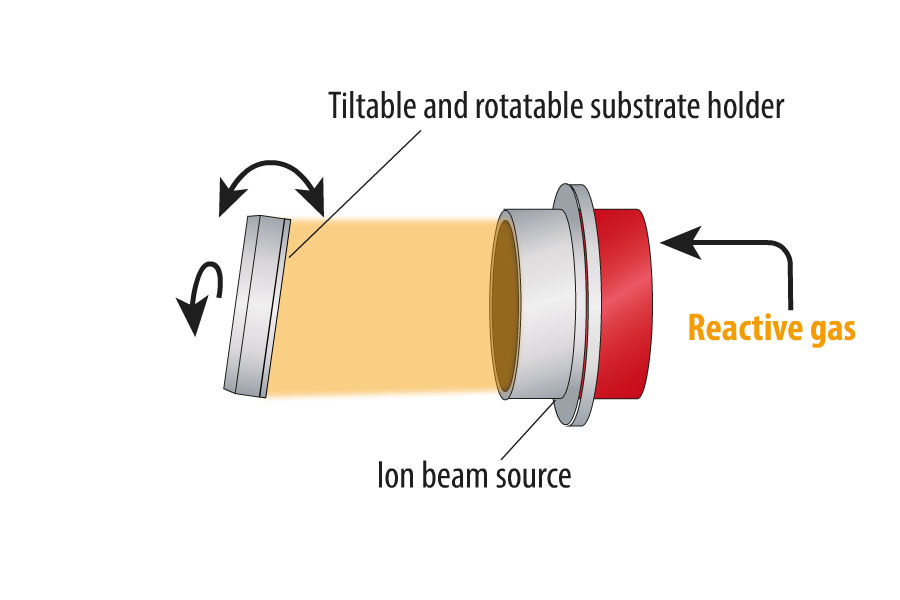

CHEMICALLY ASSISTED ION BEAM ETCHING (CAIBE)

The chemically assisted ion beam etching uses the technology of ion beam milling or ion beam trimming and adds additional reactive gases close to the substrate, typically by a gas ring. This can lead to increased etching rate or higher material selectivity of the etching process.

Related Systems

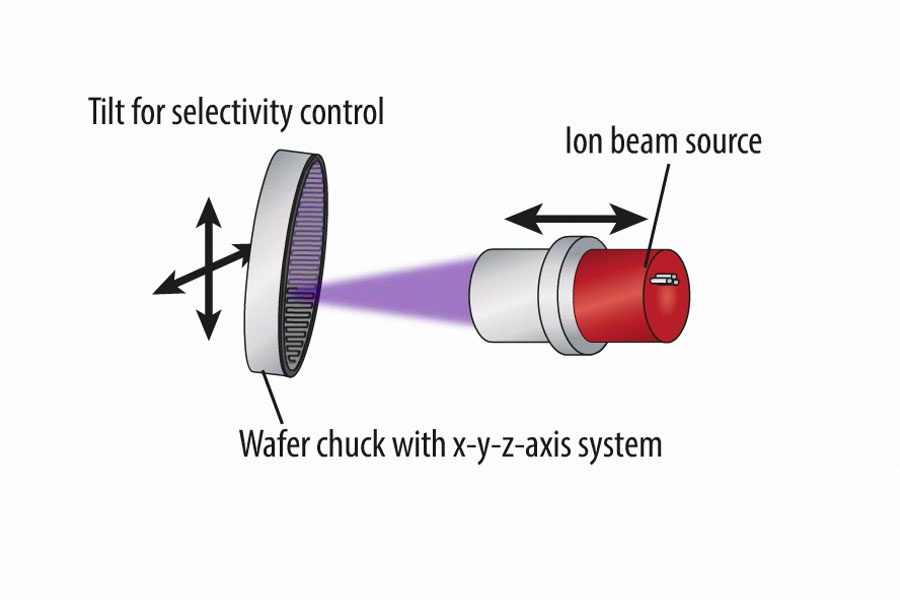

ION BEAM TRIMMING (IBT)

Ion beam trimming is a special type of IBE using a small beam of positive charged ions, e.g. Ar+, to physically etch material from a substrate by ion bombardment. A beam width of typically of 7 … 15 mm (FWHM) ensures a sufficient lateral resolution and a high throughput. During the trimming process a focused broad ion beam moves in a meander-shaped pattern across the substrate surface. By altering the local dwell time it is possible to precisely adjust the material thickness, and hence e.g. device properties like the frequency of an acoustic filter (SAW, BAW).

Reactive Ion Beam Trimming (RIBT) introduces reactive gas into the ion beam source for reactive structuring of the surface.

Related System

ION BEAM FIGURING (IBF)

Ion beam figuring is an ion beam trimming process applied on optical substrates. It is a polishing error correction by a scanning ion beam and dwell time control to adjust the surface form error of curved substrates such as aspherical lenses to an order of precision, which is not accessible with any conventional polishing technologies.

Related System

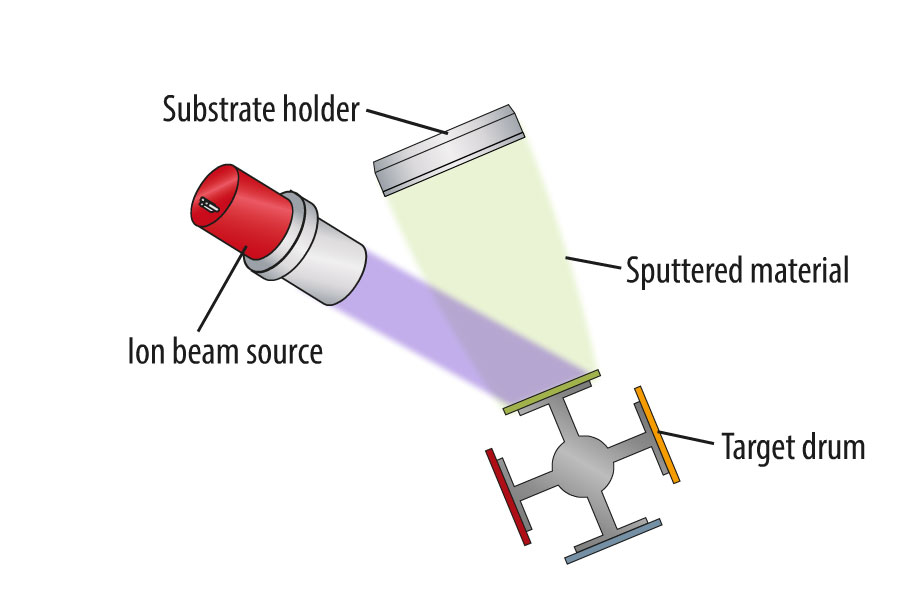

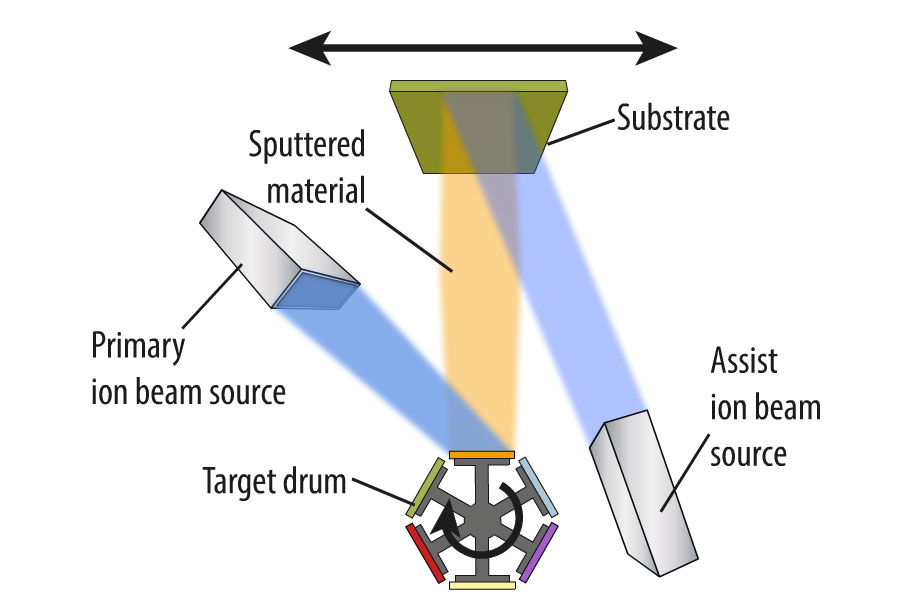

ION BEAM SPUTTERING (IBS)

Ion beam sputtering or ion beam deposition (IBD) requires an ion beam which is facing a target. The resulting ion bombardment physically removes material from the target which is deposited on the substrate surface and leads to layer growth. The low sputtering pressure and the low process temperatures enable a dense layer growth and outstanding layer properties such as refractive index and low absorption losses. The adding of reactive gases such as oxygen allows reactive ion beam sputtering of e.g. dielectric materials.

Related Systems

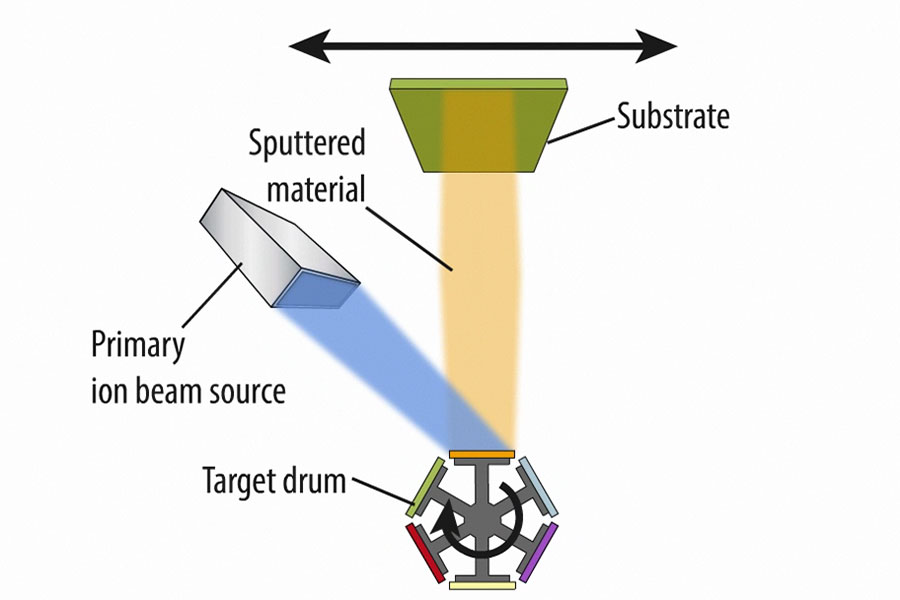

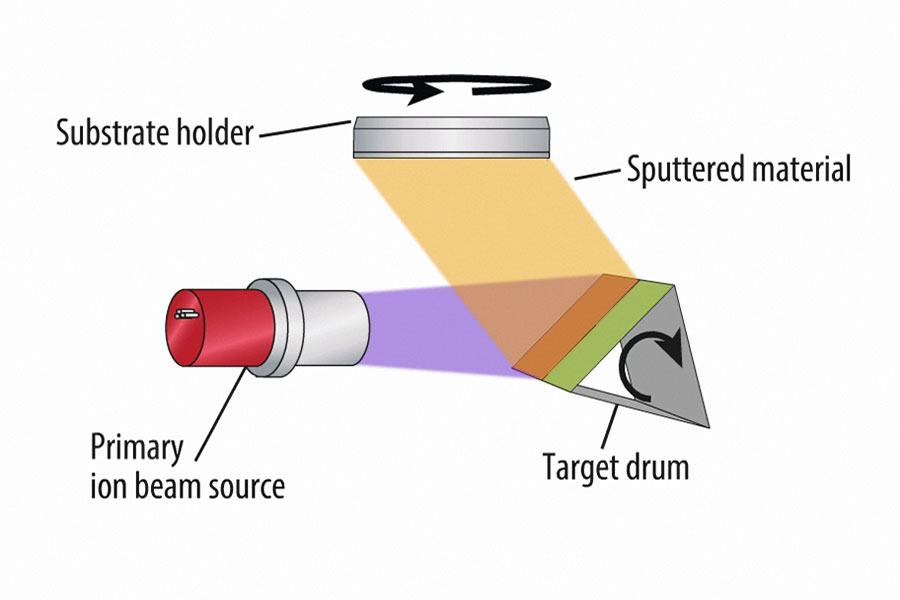

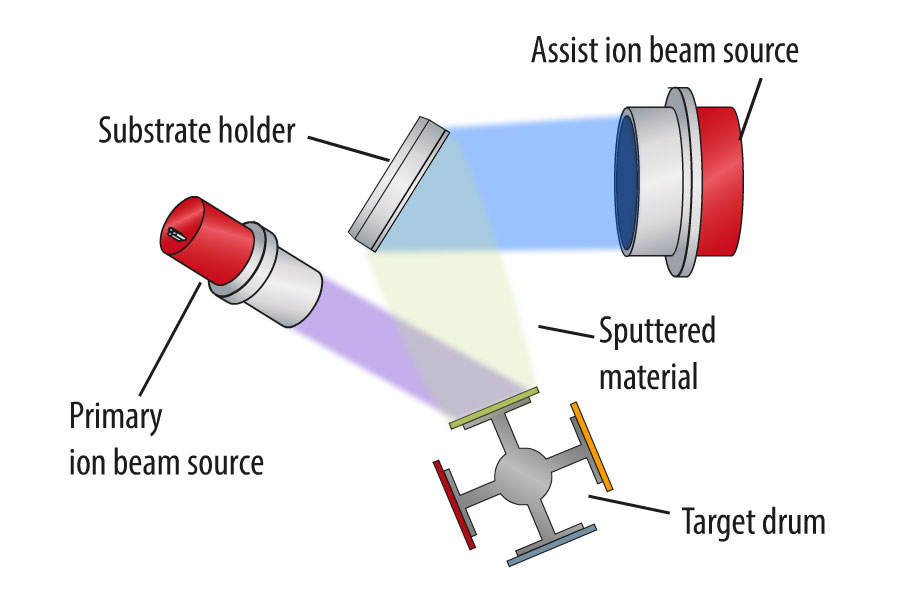

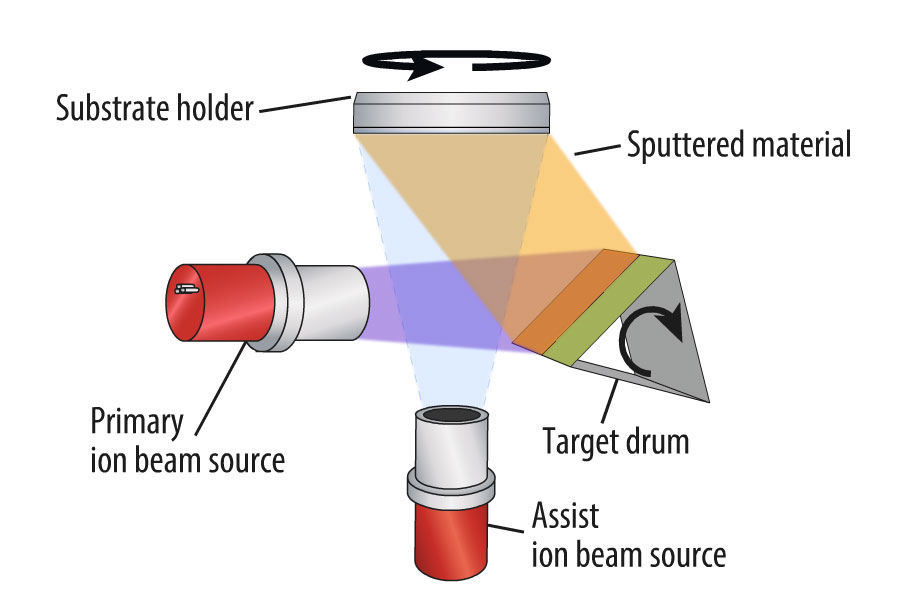

DUAL ION BEAM SPUTTERING (DIBS)

By adding an additional assist ion beam source to the ion beam sputtering setup an extra ion bombardment at the substrate can be introduced. This is used to influence the growing film or pre-clean the substrate before sputtering.

Related Systems

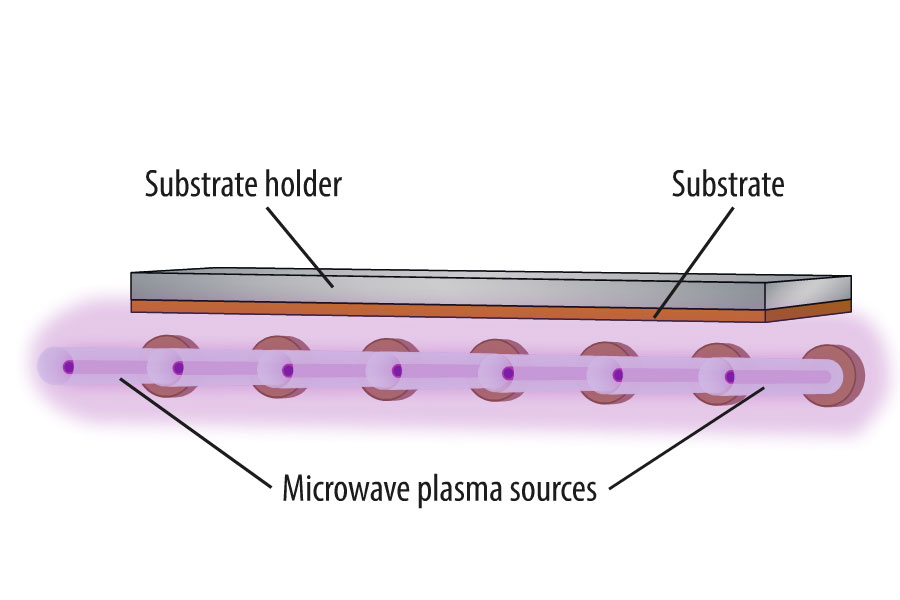

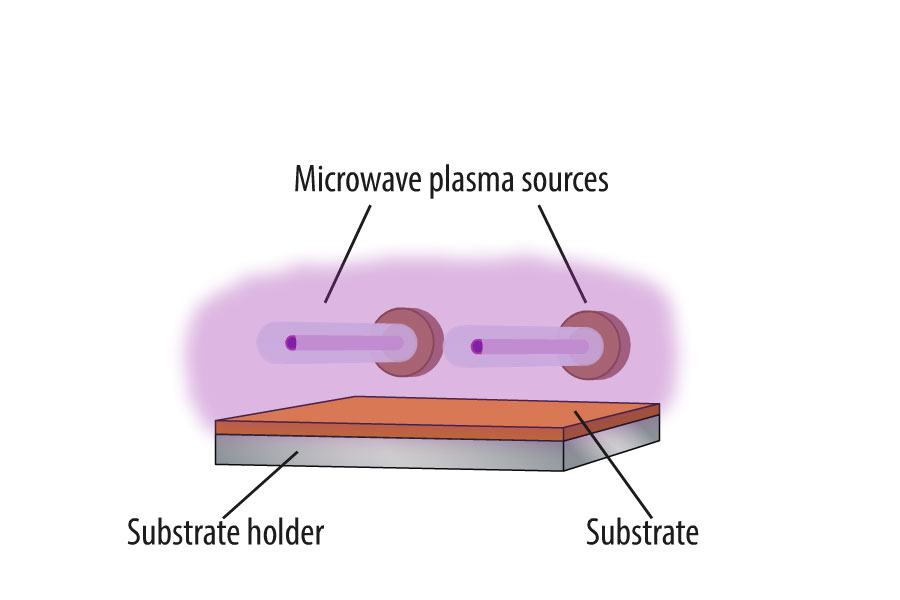

PLASMA ENHANCED CHEMICAL VAPOR DEPOSITION (PECVD)

Plasma enhanced chemical vapor deposition is a plasma assisted reactive process to deposit thin films from a gas state (vapor) into a solid state on a substrate. This process requires precursor gases, which need a plasma excitation to get vaporized and finally condensing on the substrate surface. Typically, the plasma excitation is done by a RF electrode setup or microwave antenna setup. Compared to thermal CVD the temperature during PECVD is low, because chemical reactions are activated by plasma and not be high temperature.

Related Systems

REACTIVE ION ETCHING (RIE)

Reactive ion etching uses reactive gases and ion bombardment for physically and chemically etching of substrate surfaces. Reactive gases are ionized by plasma excitation to etch into substrate materials. Plasma excitation is typically done by a RF electrode or microwave antenna setup. The high reactivity allows high material selectivity, adjustable trench profiles, and high etch rate.

Related Systems

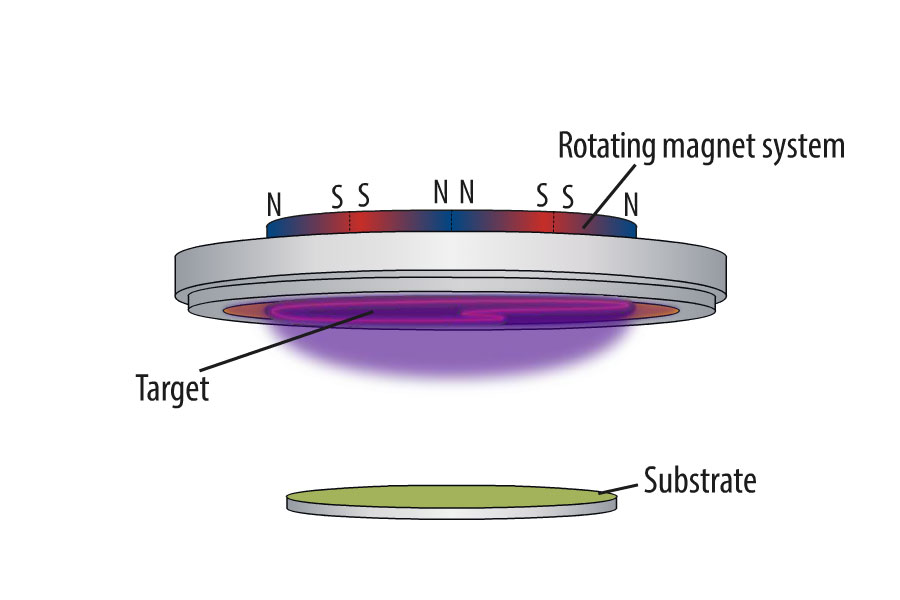

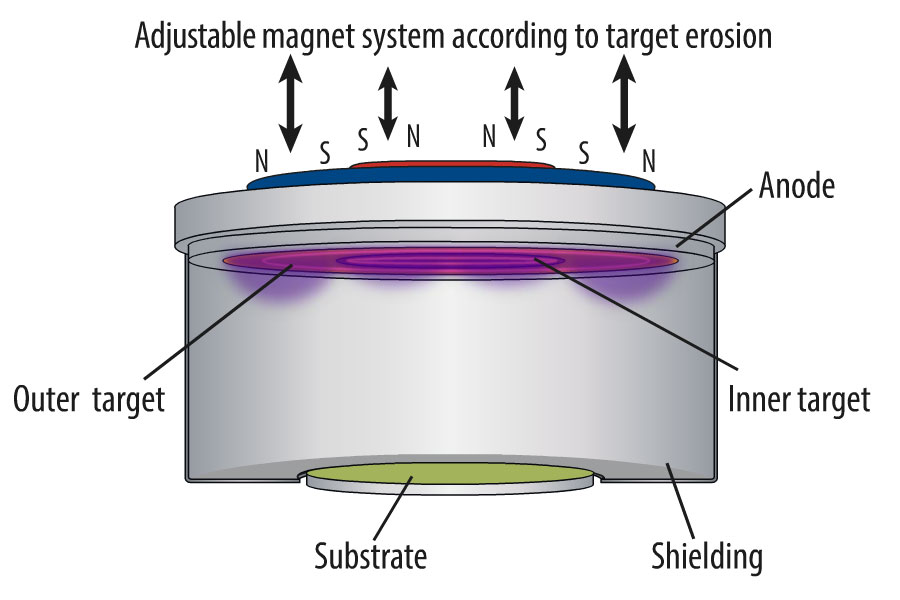

MAGNETRON SPUTTERING (PVD)

Magnetron sputtering uses a cathode with a permanent magnetic field to excite a dense plasma at the cathode surface, where the target material is placed. The resulting ion bombardment physically removes target material, which is moving to the substrate surface. The adding of reactive gas such as oxygen allows reactive magnetron sputtering. Thereby, dielectrics can be sputtered from a metallic target. This allows high sputtering rates together with good layer properties such as refractive index.

Different sputter setups allow a broad range of applications:

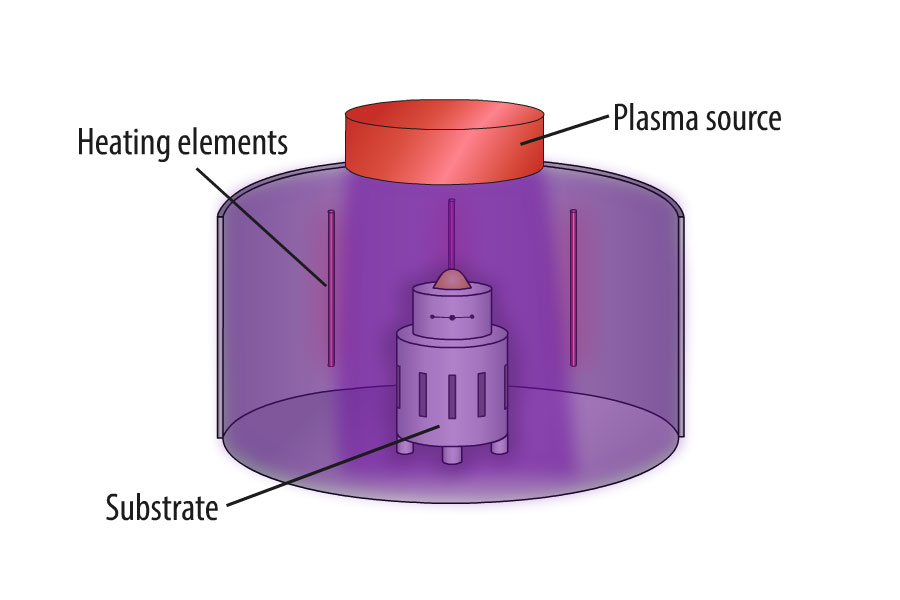

Static deposition with single magnetron

The process chamber contains one magnetron with rotating magnetic field with a target diameter larger than the substrate diameter.

Related System

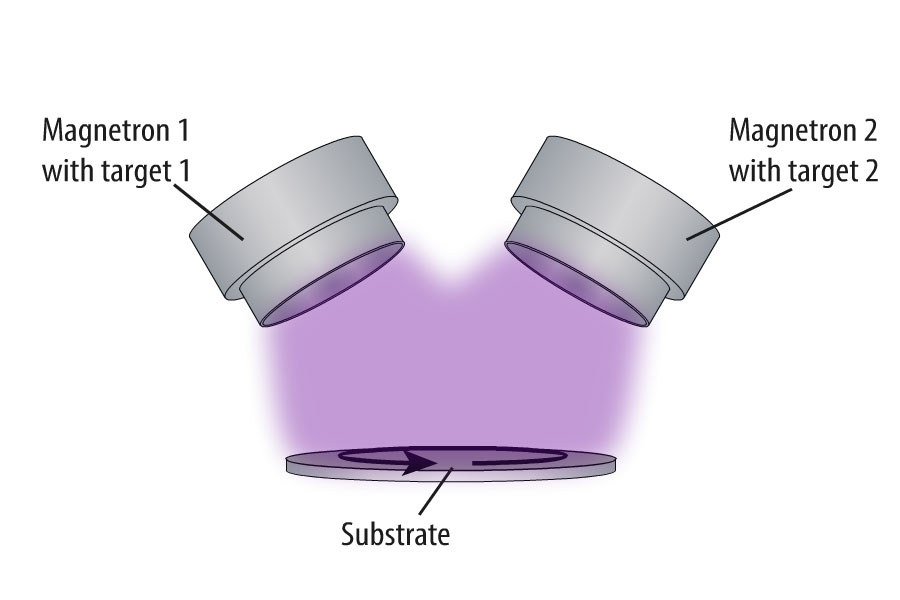

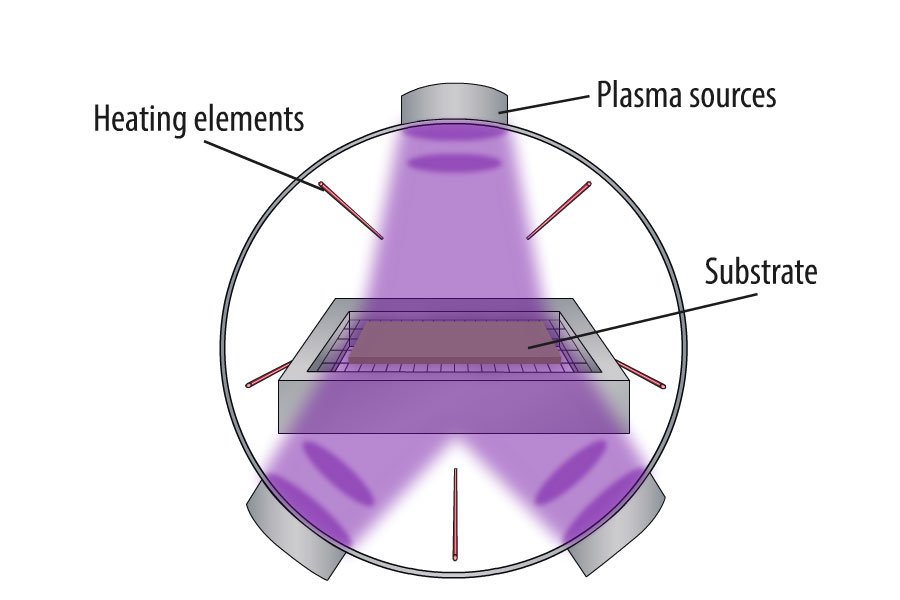

Confocal Sputtering

The sputter arrangement consists of up to 4 Magnetrons, each with target diameter smaller than substrate diameter.The magnetrons can be combined for co-sputtering of alloys (different target materials) or for bipolar sputtering (same target materials).

Related Systems

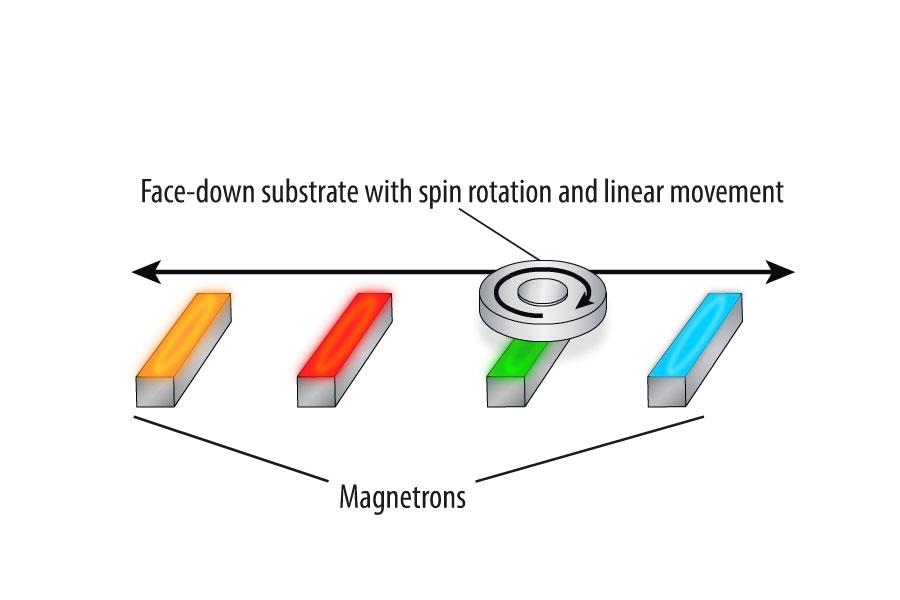

Dynamic deposition

Linear or orbital movement of the rotating substrate across rectangular magnetrons for precise multilayer coatings on large substrates.

Related Systems

ELECTRON BEAM (E-BEAM) EVAPORATION

Current through tungsten filament causes electron emission, which accelerates to an e-beam by high voltage. A magnetic field deflects the e-beam so that it is focused into the crucible. This leads to evaporation of target material and deposition on the substrate.

E- Beam Evaporation + Ion Beam Assistance

An additional ion beam source is used to pre-clean the substrate.

Related Systems

DRY-CLEANING

Dry-cleaning allows the removal of substrate surface contaminations in vacuum with different methods. These methods can be applied successively to optimize the cleaning results.

Vacuum desorption

Vacuum desorption is, where contaminants are removed from a substrate using ultra high vacuum.

Thermal desorption

Thermal desorption utilizes heat to increase the volatility of contaminants to remove them from the substrate. For example water can be removed effectively by heating the substrate with infrared or resistance heater.

Plasma treatment

Plasma treatment uses a plasma to support the removal of the contamination. Low ion energy oxygen plasmas help to reduce hydrocarbons or remove photoresist.

High ion energy bombardment

High ion energy bombardment introduced by a RF electrode or ion beam source physically remove the first nanometers of the substrate material e.g. native oxide on a silicon wafer.

Related Systems

Any questions left?

Our team will be happy to help you find the optimal technology and system configurations for your manufacturing needs. Please contact us for more information:

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Germany