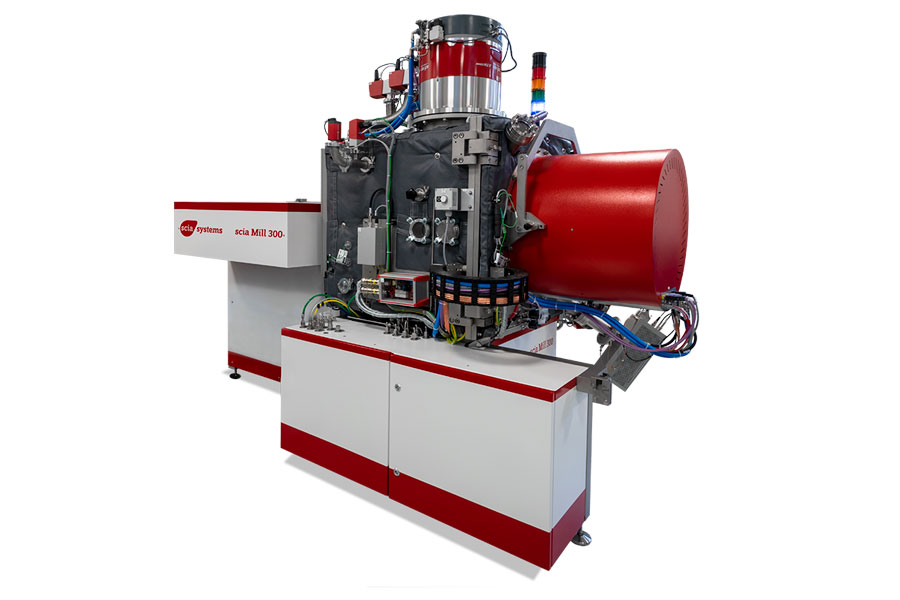

Substrate size (up to) | 300 mm dia. |

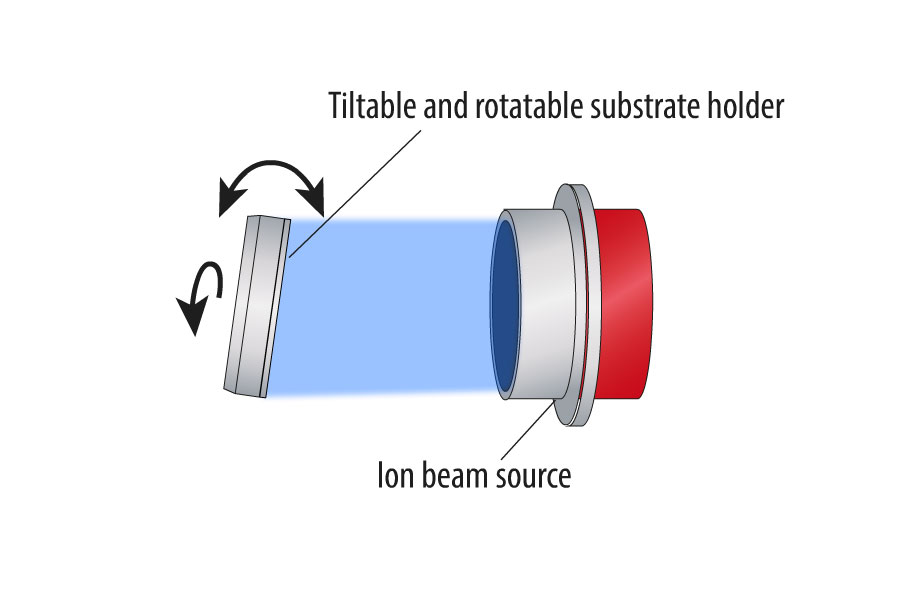

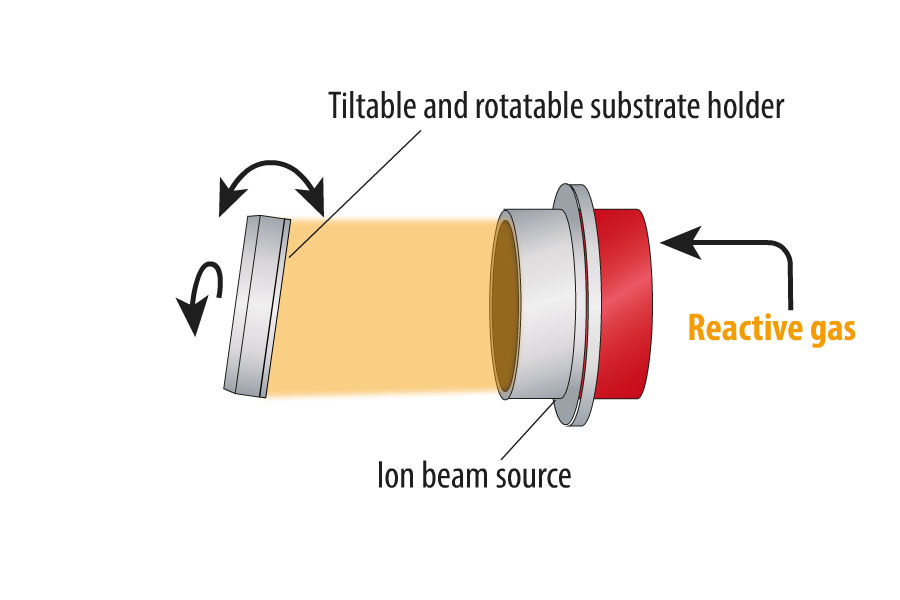

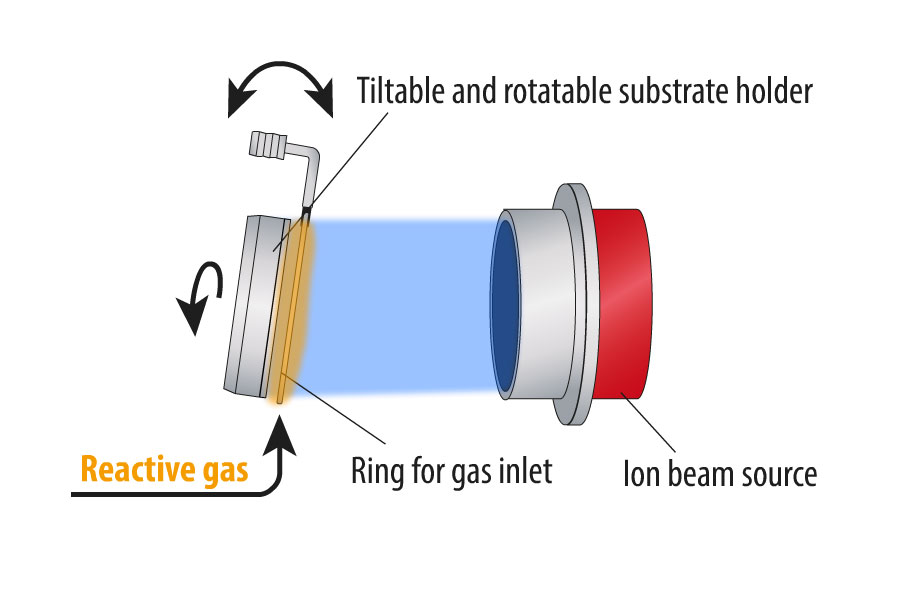

Substrate holder | Water-cooled, helium backside cooling contact, substrate rotation 1 to 20 rpm, tiltable in-situ from 0° to 170° in 0.1° steps |

Ion beam source | 450 mm circular RF source (RF450-e) |

Neutralizer | RF plasma bridge neutralizer (N-RF) |

Throughput | 12 Wafer/h (100 nm SiO2 removal) |

Base pressure | < 5 x 10-7 mbar |

System dimension (W x D x H) | 2.70 m x 1.50 m x 2.00 m, for single chamber with single substrate load-lock (without electrical racks and pumps) |

Configurations | Single chamber, optional single substrate load-lock or cassette handling, |

Software interfaces | SECS II / GEM, OPC |