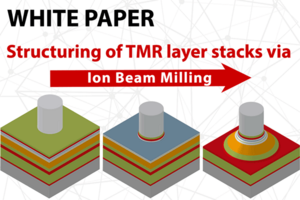

White Paper

Ion Beam Milling for Structuring of Tunnel-Magneto-Resistance Sensors

We demonstrate that high quality tunnel-magneto-resistance (TMR) sensors composed of CoFeB/MgO/CoFeB magnetic tunnel junctions (MTJs) can be produced by using ion beam etching to structure the layer stack with a scia Mill 200. Background information about the MTJs functionality as well as sample preparation and the ion beam milling process are given. Required tool capability, such as helium backside cooling and etching uniformity, are analyzed. Finally, the MTJs were characterized by measuring the electrical resistance in a magnetic field.

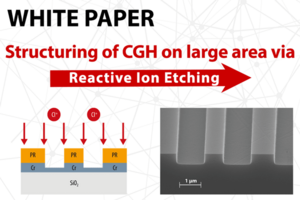

Reactive Ion Etching of Large-Area Computer Generated Holograms

The fabrication of Computer Generated Holograms (CGH) on large areas requires dry-etching methods and systems capable for the large substrate sizes. In this work, we demonstrate the CGH structuring with a size of 450 mm x 450 mm using the dry-etching system scia Cube 750. The process consists of three steps: (i) structuring of the hard mask, (ii) ashing of the photoresist (PR) and (iii) etching into the quartz. Properties such as selectivity, loss of critical dimension (CD), and etching uniformity were investigated.