Ion Beam Trimming and Ion Beam Figuring: Precise Surface Modification for Next-Generation Applications

Ion beam trimming and ion beam figuring are advanced high vacuum techniques used for precision surface modification and correction in various fields, including optics, microelectronics, and nanotechnology

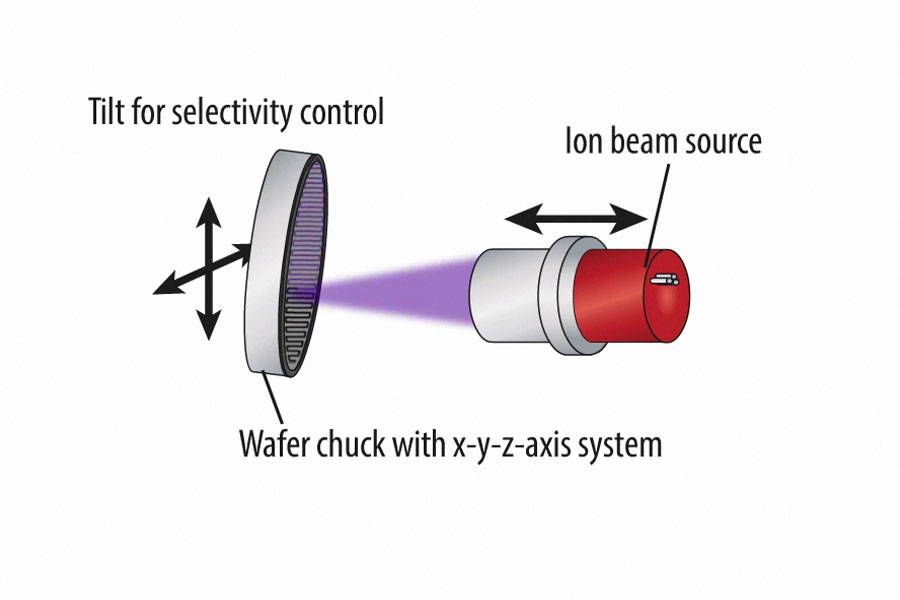

Unlike conventional mechanical polishing methods, both IBT and IBF processes operate without physical contact. A focused broad beam of positive charged ions, e.g. Argon, moves across the substrate surface. The collision of the ions with the atoms of the substrate starts a "collision cascade", causing individual particles to detach from the surface. The amount of removal is controlled by the duration of processing. The longer the ion beam stays at one spot, the more material is removed. Since both forms are physical processes, a wide range of materials can be processed.

Ion Beam Figuring is a special form of ion beam trimming for polishing error correction of optical substrates. It is also often referred to as ion beam polishing or ion beam finishing, as it is usually the last step in a series of processing steps.

Advantages of ion beam trimming & ion beam figuring:

- High precision: processing with extremely high surface accuracy and single nanometer figure correction.

- Non-contact process: Therefore, ion beam trimming does not introduce mechanical stress or damage to the surrounding areas, resulting in improved device reliability.

- High selectivity by the additional use of reactive gases (Reactive Ion Beam Trimming, RIBT), making it ideal for complex device structures.

Equipment for Ion Beam Trimming and Ion Beam Figuring

High-volume production system for film thickness correction of wafers up to 200 mm

- Ion Beam Trimming

- Ion Beam Figuring

Precise surface correction for impressively uniform films on wafers up to 300 mm

- Ion Beam Trimming

- Ion Beam Figuring

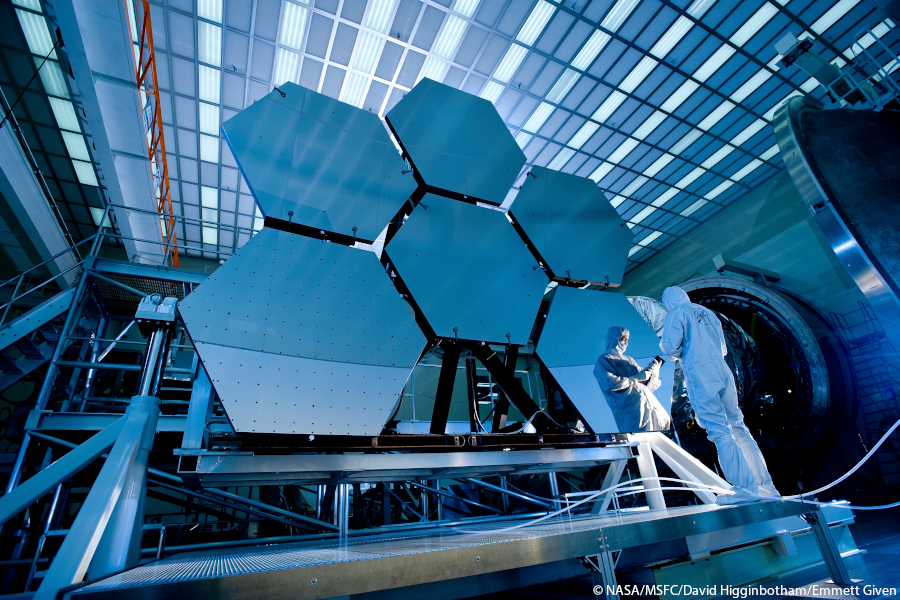

Polishing error correction of high-precision optical elements up to 1500 mm dia.

- Ion Beam Figuring

Applications

Ion beam trimming systems are used to correct geometric deviations spread over the wafer by filter manufacturers worldwide. In the production of precision optics such as mirrors and lenses, ion beam trimming can be used to correct unwanted aberrations or irregularities in the surface geometry. Ion beam trimming can also be used to create a surface relief grating with varying angle, the technical foundation for modern augmented and mixed reality glasses.

It is also used to produce micromechanical components such as sensors and actuators in order to adjust the mechanical properties.

Frequency Trimming of BAW Devices

Improved Layer Uniformities for Bulk Acoustic Wave Filters.

Thickness Trimming of POI Wafers for RF Filters

Precise layer thickness adjustment in the production of guided SAW devices.

Surface error correction of X-ray mirrors

Application Note onion beam figuring of mirrors for X-ray telescopes

Surface Trimming of SAW filters

Ion beam trimming to provide high yield in mass production of SAW filter

Film Thickness Correction of Read/Write Heads

Ion Beam Trimming of write poles of thin film heads for hard disks

Video Presentation: Ion beam figuring of telescope mirrors

Surface processing of telescope mirrors using ion beam trimming and ion beam figuring.

More Information

- Not the right system yet? See our complete portfolio.

- Overview of Ion Beam and Plasma Processing Technologies

- Tailor Made Solutions

- Contact