Ion Beam Trimming of Write Poles of Thin Film Heads

The production of hard disk read/write heads requires a complex manufacturing process with several hundred steps. Precision is crucial in order to produce a maximum yield of read/write heads with identical characteristics. The exact width of the poles influences the magnetic write field of the hard disk, which can lead to data loss if it is too wide or too narrow. A uniform layer thickness is also essential as the read/write head flies over the storage layer at high speed, and non-uniformities can cause air turbulence, damaging the surface and affecting performance.

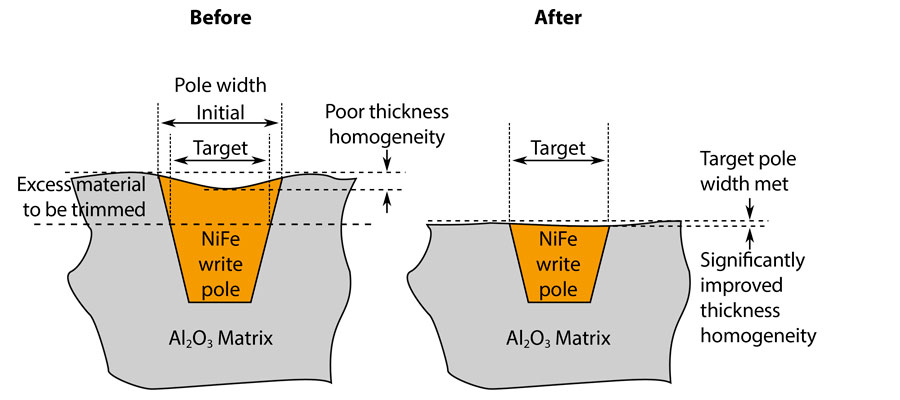

Current production equipment is reaching its limits and therefore often requires post-processing. However, the usual method, chemical mechanical polishing (CMP), can lead to an undesired step structure with extremely negative influence on the further processing steps, device handling, and thus device yield. (see Fig. 1, left).

Local ion beam etching enables precise adjustment of the layer thickness, fixing of the lateral extension of the writing pole, and surface smoothing for improved performance (see Fig. 1, right).

...

Reach out

Please contact us for further information.

Related Information

Related Product - scia Trim 200

- Pole width adjustment

- Step height reduction

- Improvement of thickness homogeneity

- Increase of device yield

- High volume production system

- Equipped with handling robot for standard semiconductor cassettes