scia Systems obtains an order for a scia Etch 300 by Ernst-Abbe-University Jena

scia Systems provides precise surface processing equipment based on advanced ion beam and plasma technologies. The systems are applicable for coating, etching, and cleaning processes, especially for the MEMS, microelectronics, and precision optics industries. The process equipment is flexible and modular in design, thus can be easily configured for research applications and for high-volume production. It suits silicon wafer-based substrate sizes, smaller samples on carriers, and optical substrates with up to 3 m diameter.

Our systems are flexible and modular in design. This enables us to offer standard as well as individual solutions for our customers.

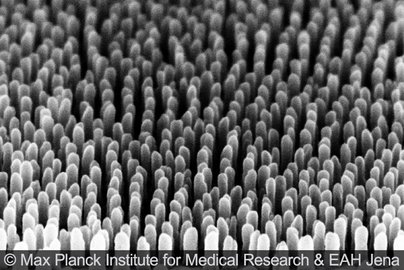

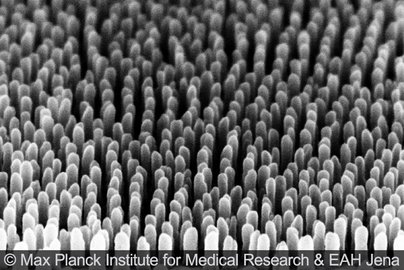

Our equipment is mainly used in the production of MEMS and precision optical components, but also in astronomy and biomedical technology.

Pushing the latest technologies with ambition and constantly evolving - that's what scia Systems is all about.

2024-04-24 to 2024-04-26

Yokohama, Japan

Booth: D-49 (Floorplan)

Partner on Site: Canon Marketing Japan