Smart devices and much smaller wearables - that's the mission Kyocera Tikitin is dedicated to. Along the way, they are developing and fabricating MEMS resonators made of silicon, deviating from the traditional use of quartz.

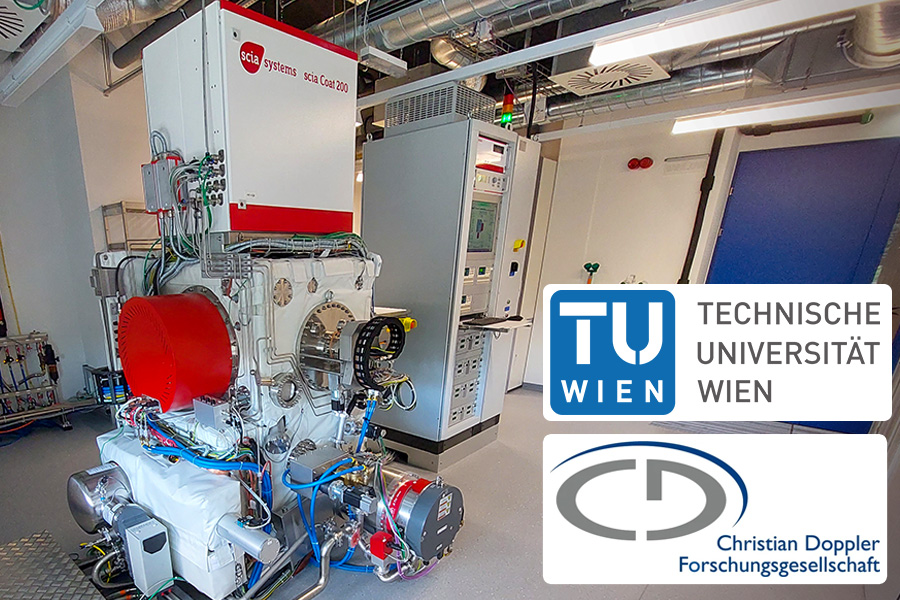

To expand their research capabilities, they added a scia Mill 200, an advanced ion beam milling system, at VTT Technical Research Centre of Finland, one of Europe’s leading research institutions.