Frequency Trimming for Bulk Acoustic Wave (BAW) Devices

High-frequency filters for mobile communications increasingly use bulk acoustic wave (BAW) filters instead of surface acoustic wave (SAW) filters for frequencies above 2.4 GHz. Not only do these filters offer more cost-effective production, they are also more compact in size and provide better performance.

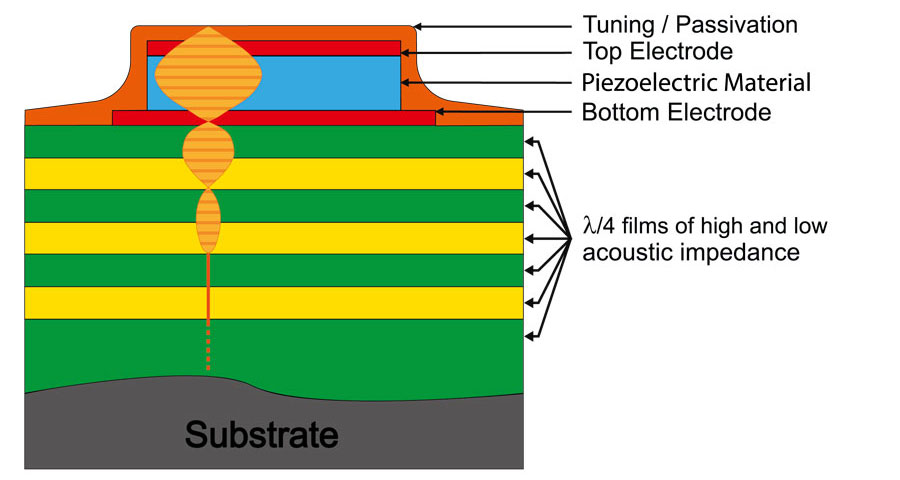

BAW filters use a piezoelectric layer commonly made of aluminum nitride. The thickness of the film must match half of the acoustic longitudinal wave to form a resonator. There are different methods to create an acoustic isolation between the resonator and substrate, such as FBAR (Thin Film Bulk Acoustic Resonator) and SMR (Solidly Mounted Resonator). The frequency of each component is adjusted at the end by trimming an additional passivation layer, e.g. silicon nitride, so that it shifts the frequency accordingly with its mass.

The requirements for the uniformity of the layers are demanding. Ion beam trimming can improve layer uniformity and increase the component yield from 10 % to 90 %.

...

Reach out

Please contact us for further information.

Learn more

Ion beam technology for thin piezoelectric films

Piezoelectric films are used in a wide range of applications, such as transducers for example in microphones, motors and resonators. The coated resonators are mainly used as frequency filters in modern mobile communications and require an excellent quality of piezoelectric coating. In his presentation, Karl Gündel, Technical Sales Manager at scia Systems, will talk about the advantages of ion beam technology in the production of these piezoelectric layers.

Related Information

Related Product - scia Trim 200

- Thickness trimming, mass load trimming, acoustic mirror layer trimming to improve yield

- Increase in device yields to over 90 %

- High volume production system

- Equipped with handling robot for standard semiconductor cassettes

Any questions left?

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Germany