Ion Beam Figuring of X-Ray Mirrors

X-ray astronomy has made significant contributions towards understanding the evolution of the universe. Many astronomical objects emit radiation in the X-ray band that can be analyzed to gain knowledge about the evolution of black holes, supernovae and structure of galaxies.

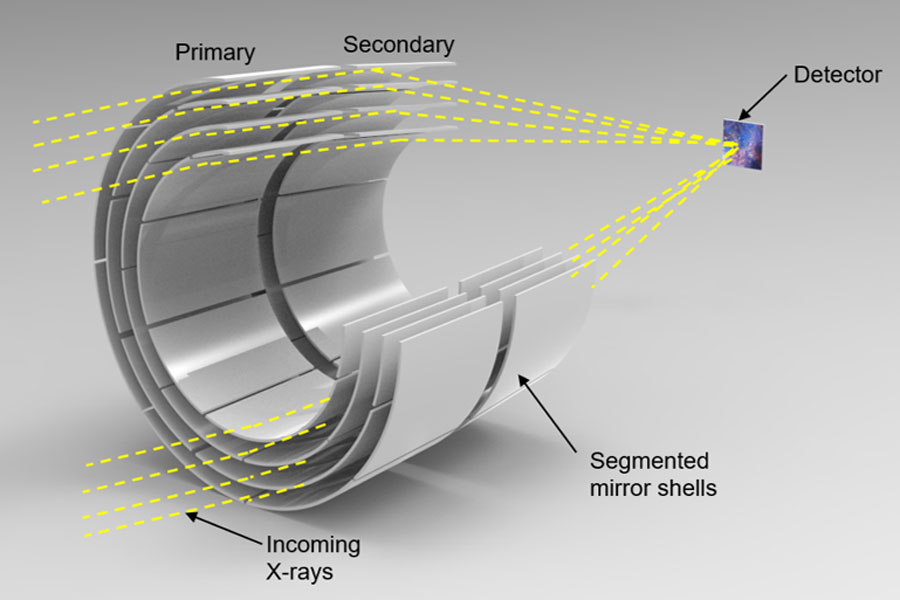

X-ray telescopes must be operated in space, due to absorption of X-rays by the earth’s atmosphere. Because of the short wavelength of X-rays, focusing mirrors must be aligned for grazing incidence of light. As the objects being studied have a low delivery of radiation (a few photons per hour), every single photon is of particular interest. To increase collection efficiency, hundreds or thousands of mirrors are nested concentrically, as in a Wolter telescope (see Fig. 1). To ensure good image quality, the surface geometry of the reflective X-ray mirrors must be as close to ideal as possible. Any deviation between the ideal mirror geometry and the real mirror geometry is critical for imaging quality.

The basic shape of the mirrors is made from silicon blocks which at first are brought into shape by mechanical machining. After that, chemical mechanical polishing (CMP) is applied to the reflecting side. However, due to the rectangular shape of the mirrors and their curvature, the residual error of CMP processing is still several hundred nanometers in range. This residual error can be corrected by means of ion beam figuring (IBF).

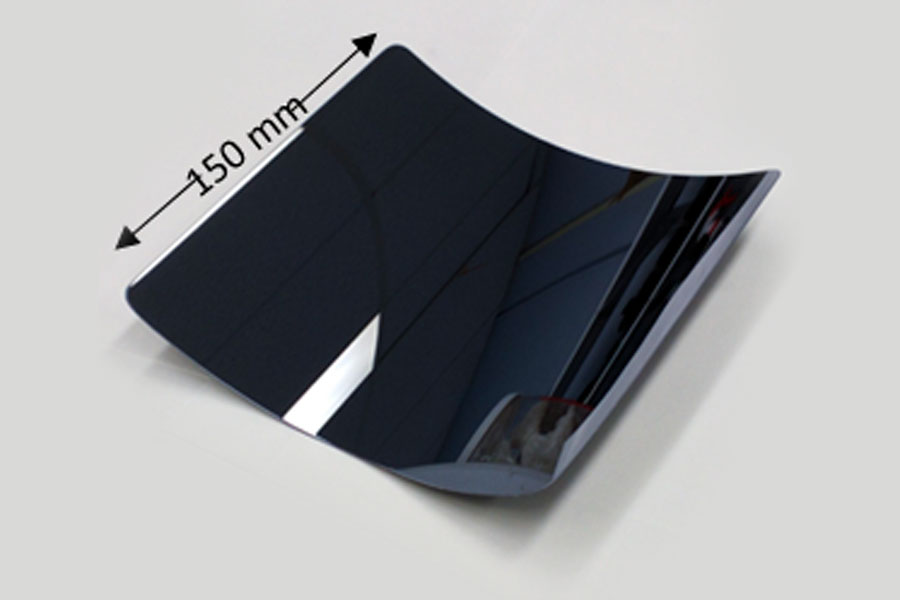

In this example, scia Systems GmbH has applied IBF to mirrors provided by the NASA Goddard Space Center (see Fig. 2). The ion beam figuring is performed by a focused ion beam (FWHM < 10 mm) that scans over the mirror surface in a meander-like path. A position-dependent varying dwell time leads to a precise removal of the amount needed to correct form errors. The removal rate of the beam is determined not only by the material and ion beam energy, but also by the angle of incidence of the ion beam (see Fig. 3). Due to this angular dependency of removal, the contour of the mirror must be taken into account. Based on the measured form error distribution and the mirror contour, the dwell time map can be calculated.

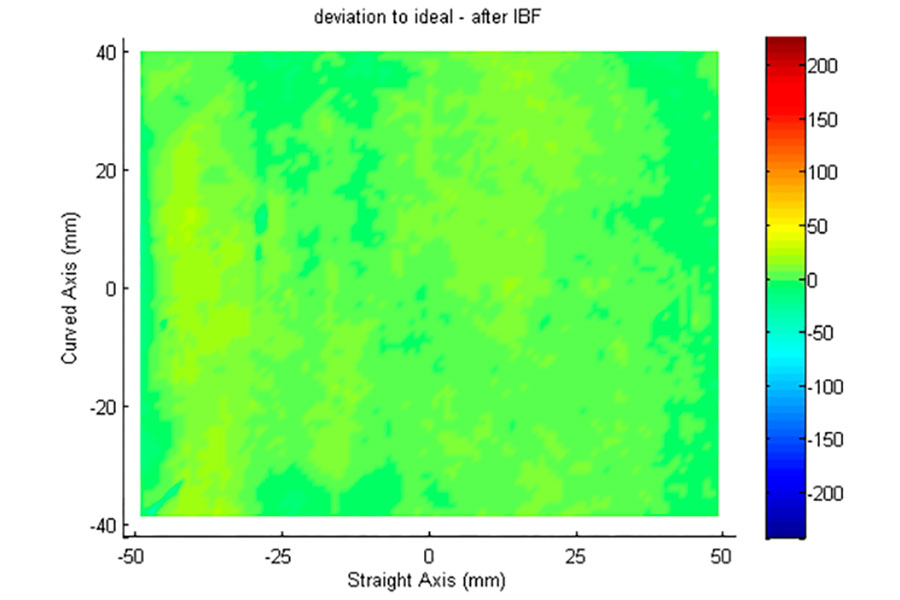

Sample mirrors from NASA were treated by IBF using a scia Trim 200 ion beam figuring system. The pre-IBF error distribution is shown below (see Fig. 4a) as well as the post-IBF error distribution (see Fig. 4b). The RMS residual error after a single IBF step can be reduced by a factor of more than 14 and values in the single-digit nanometer range can be achieved.

By applying a second ion beam figuring step with smaller ion beam size the remaining residual error can be reduced even further.

Reach out

Please contact us for further information.

Learn more

Ion beam figuring for telescope mirrors of different sizes

In this video presentation, Marcel Demmler introduces the ion beam figuring technology for surface error correction of telescope mirrors under high vacuum conditions. At the end of the session, he presents process results to demonstrate the nanometer accuracy of ion beam figuring.

Related Information

Related Product - scia Trim 200

- Reduction of deviation between ideal and real mirror surface

- Production system for high throughput

- Automatic handling system available

Ion beam figuring for bigger substrates can be realised by scia Finish 1500.

Any questions left?

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Germany