Ion Beam Sputtering for High- and Anti-Reflective Coatings

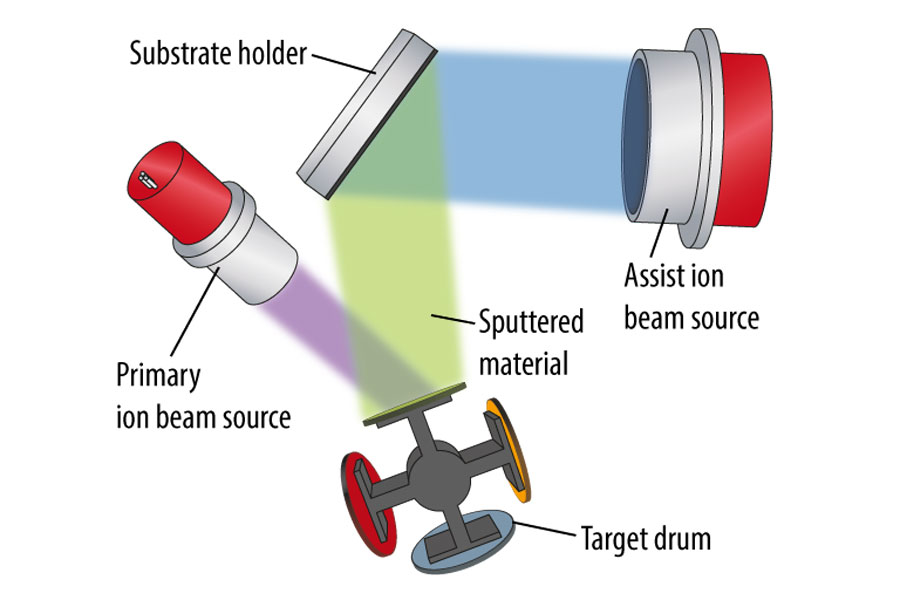

Ion beam sputtering is well-established in research and industry for optical coatings. Typical applications are coatings of precision optics, like filters, mirrors, and beam splitters. Optical multilayer stacks benefit from the high mobility of the sputtered particles on the substrate surface, and hence the good mechanical characteristics of the layers. The principle of ion beam sputtering is the ejection of target material by bombardment with high energy ions (see Fig. 1). The control of the ion energy allows material removal with Angstrom accuracy. In contrast to magnetron sputtering the low base pressure of 10-4 mbar and temperatures below 100 °C result in low contamination and high quality coatings. This is further supported by the higher energy (mobility) of the incoming material on the substrate compared to magnetron sputtering or thermal evaporation. Thus, also the density of the deposited material is usually larger by enhanced self-organization processes. These film properties make ion beam sputtering the preferred deposition method for high quality optical coatings.

If the deposition is additionally supported by a second ion beam source, the film properties can be further adjusted. An additional ion irradiation of the substrate surface can be used for a substrate pre-cleaning process, to remove especially organic contamination. Furthermore, the secondary ion beam source can be used for reactive sputtering, for a further densification of the growing film or surface smoothing/structuring.

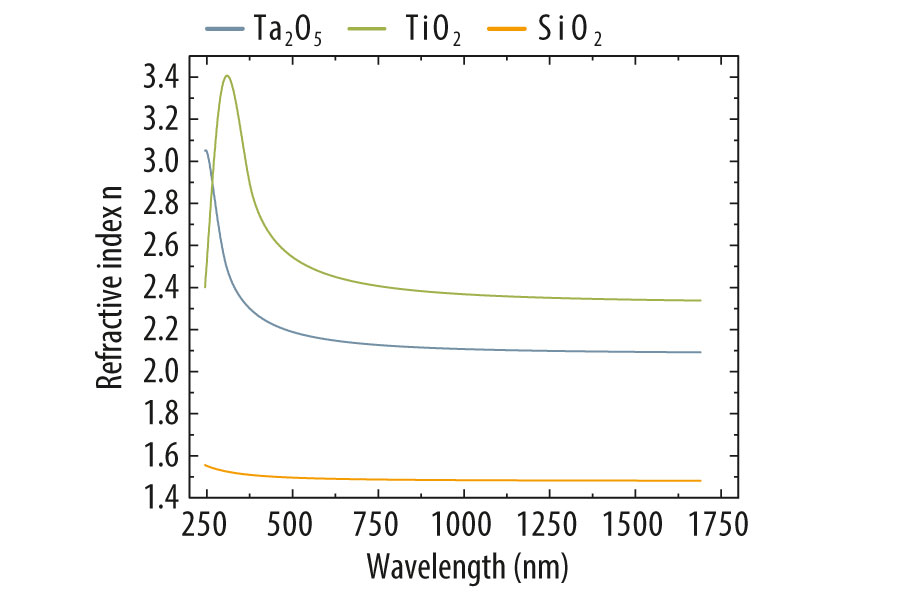

For coatings in the visible and near-infrared wavelength regions oxides are usually used due to their negligible absorption in this range. Furthermore, oxides are stable in air and usually hazard-free. They have a relatively large hardness and a lot representatives are inexpensive and also well-known. The most important representatives are SiO2, Ta2O5, TiO2, HfO2, ZrO2 and Al2O3. Oxide thin films can be deposited in the scia Systems deposition systems either reactivly, by ion beam sputtering of an elemental target in oxygen atmosphere, or by direct sputtering of an oxide target.

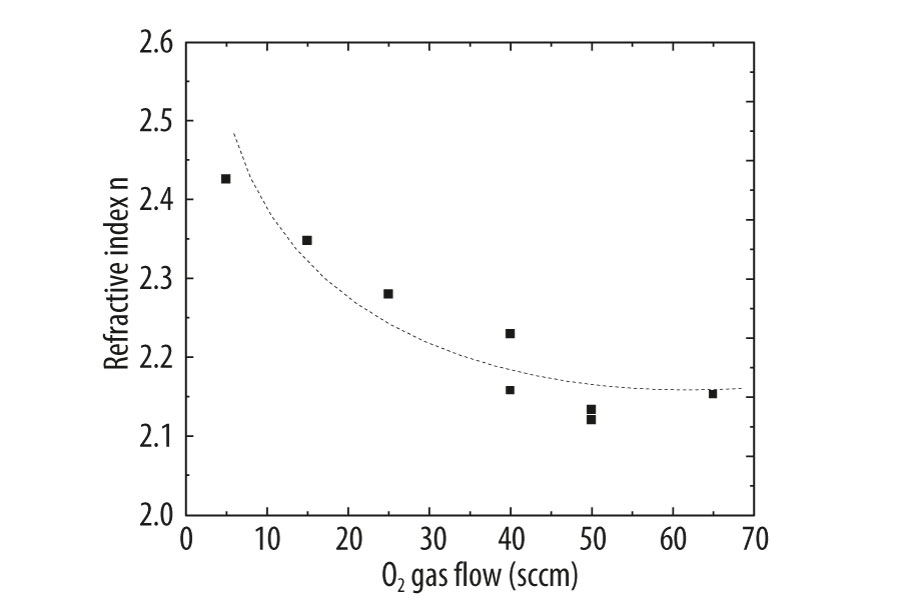

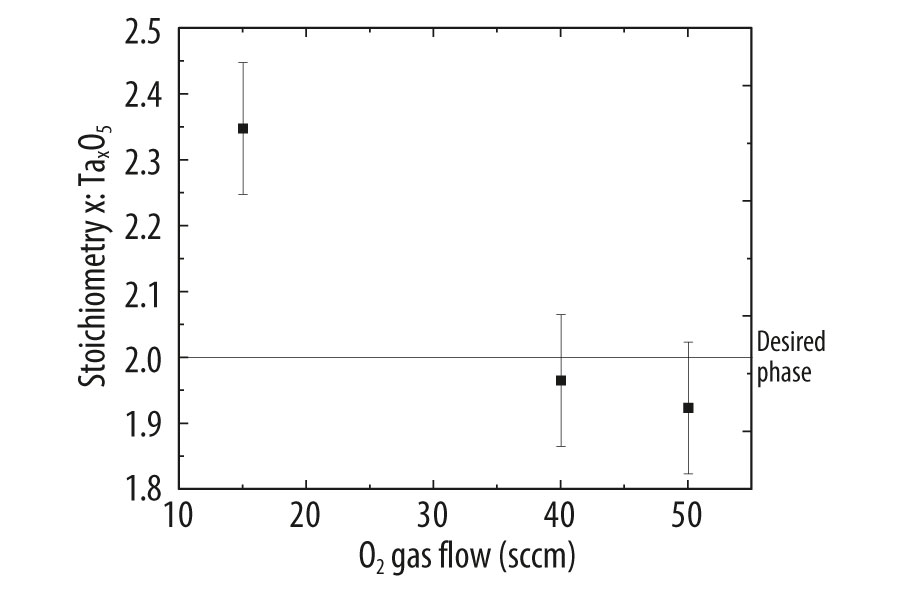

For complex optical coatings at least two different oxides with a significantly different refraction index have to be combined. Therefore, the properties of the single oxide layers have to be well-known and accurately controlled. Besides the knowledge of the exact dispersion (refractive index over wavelength) the control of the stoichiometry is very important. Deviations from the nominal stoichiometry of the desired oxide result in an increased absorption, which is e.g. critical in case of laser optics. Both parameters for reactive ion beam sputtering strongly depend on the oxygen flow into the chamber. The change of stoichiometry and refractive index in dependence of oxygen flow is shown for Ta2O5 in Figure 2 and 3.

The dispersion of some oxides, deposited with the scia Coat 200, are presented in Figure 4. The choice, which oxide is used for a specific multilayer design, depends on the required wavelength of the optical component, economic aspects and the type of application (e.g. large bandgap material like HfO2 is needed for high power laser applications).

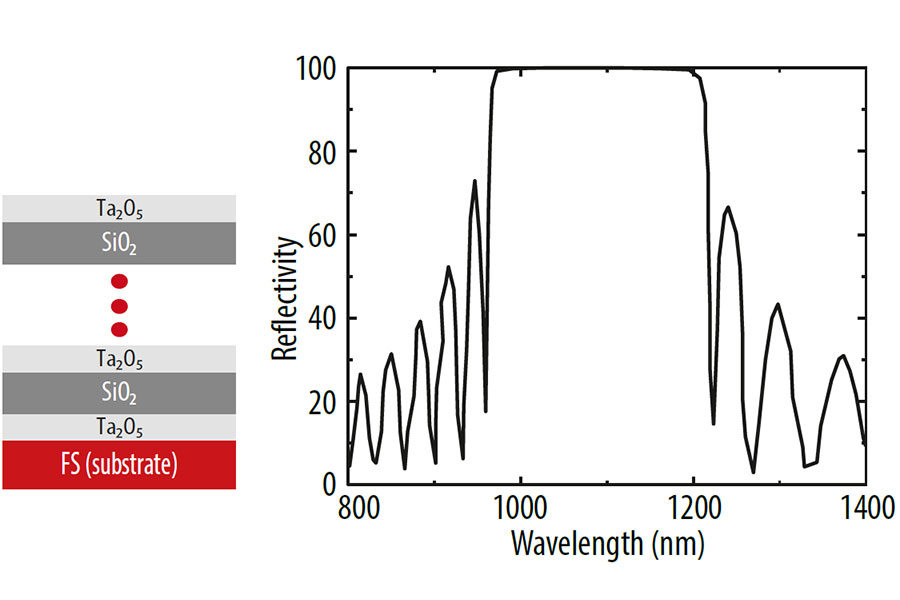

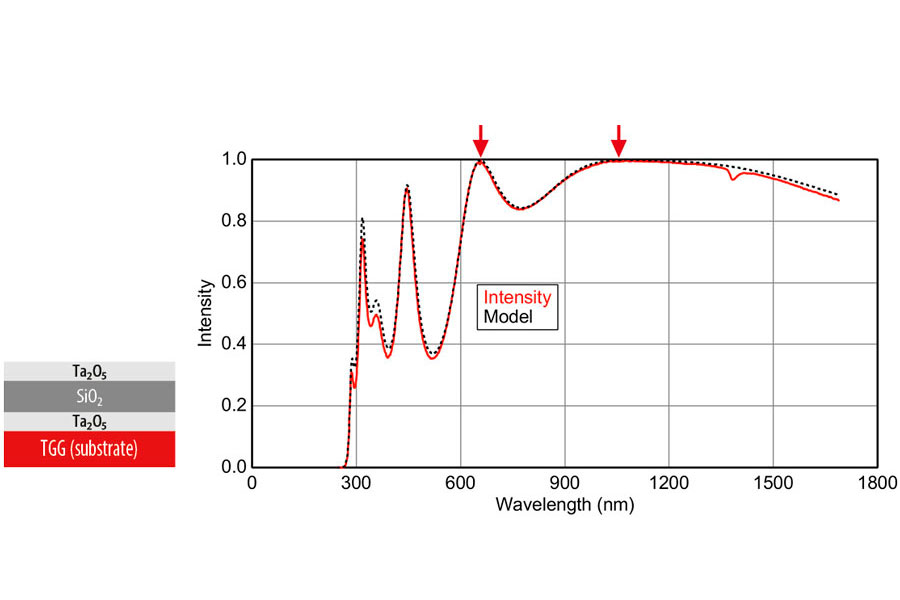

Figure 5-6 show two examples of dielectric multilayer coatings with defined properties. First, a high-reflective mirror coating is deposited in quarter-wave design using 31 individual layers of Ta2O5 and SiO2. This results in a reflectivity larger than 99.9 % for a wavelength of 1064 nm (see Fig. 5). The roughness of the layer stack on Si substrate was measured using atomic force microscopy (AFM) and a value of 0.2 nm was obtained. This is slightly larger than the initial value of 0.15 nm for the uncoated Si substrate. In addition, the SEM cross-section image shows uniform layers with sharp interfaces. Second example is a 3-layer anti-reflective coating consisting of Ta2O5 and SiO2 on a TGG substrate, which should be transparent for 633 nm and 1064 nm according to the corresponding typical laser lines. As shown in Figure 7 the transmission at 1064 nm is < 0.01 % .

Reach out

Please contact us for further information.

Related Information

Related Products - scia Coat 200 and scia Coat 500

- In-situ change of coating materials due to rotational target holder with up to 5 water cooled targets

- Controlled multilayer deposition based on process recipe

- Process monitoring with quartz crystal oscillator and/or optical thickness monitor (OTM) and test glass changer

- Direct wafer handling or adaptation to variable substrate sizes with carrier handling