Deposition of Diamond-Like Carbon (DLC) Films

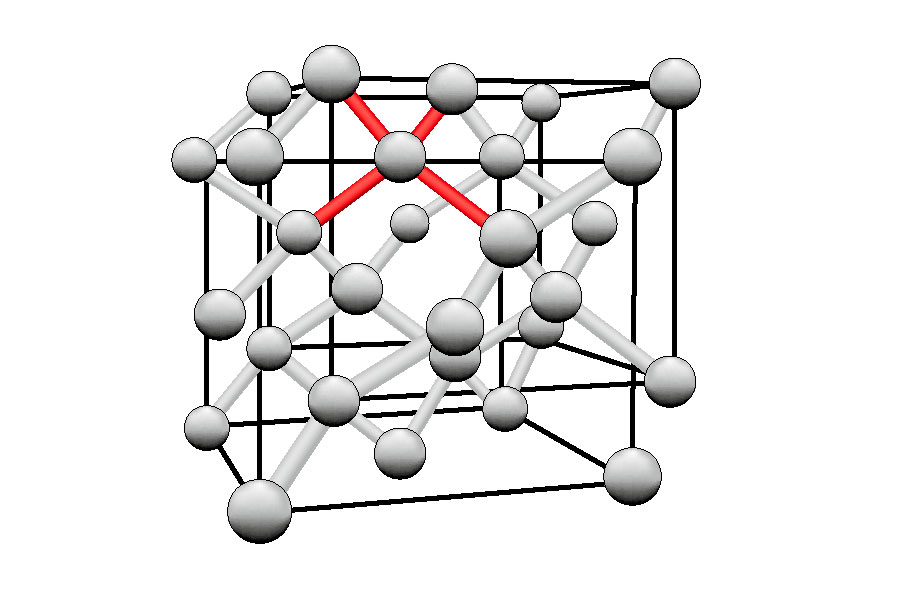

Elementary carbon can crystallize into different types of lattices and disordered structures, due to the three different hybridizations possible in chemical bonds. Well-known are diamond with sp3 hybridization (tetragonal structure) and graphite with sp2 hybridization (hexagonal planes) (see Fig. 1 and 2).

Diamond provides remarkable physical properties, like the largest thermal conductivity, the smallest thermal expansion, and the largest hardness of all known natural materials. However, the synthesis of diamond is very complex and expensive.

A way to benefit from the unique properties of the sp3 hybridization of carbon, with much lower production costs, is the synthesis of diamond-like carbon (DLC). DLC is an amorphous form of carbon with a significant fraction of sp3 bonds, and thus with akin properties as diamond.

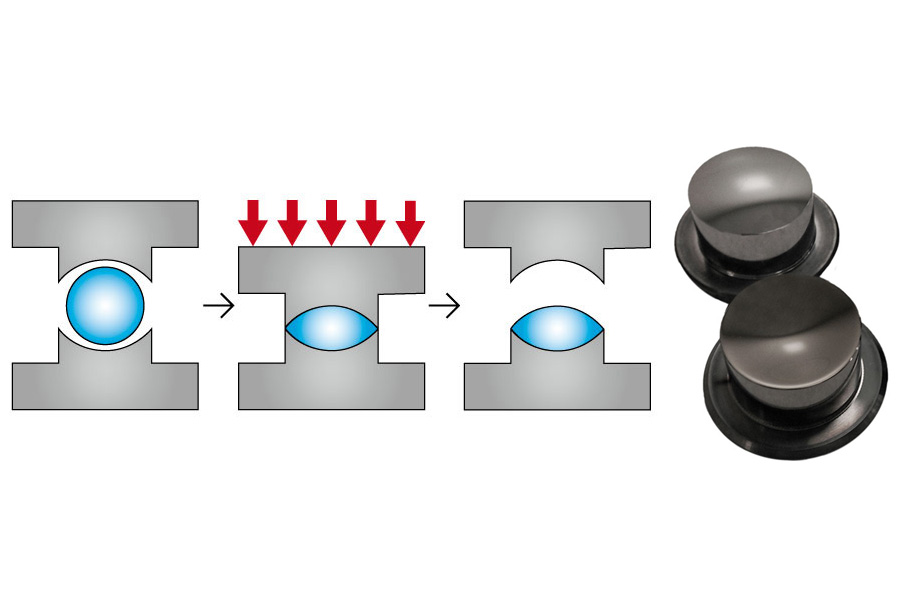

The high hardness of this material is useful for protective coatings of tools, hard discs, MEMS, or optics (esp. EUV-optics). Another application is the coating of compression molds for ultra-precise glass molding. These are used in lenses manufacturing for infrared cameras and medical systems (see Fig. 3).

Synthesis of DLC films

DLC features sp2 and sp3 hybridization of the carbon atoms, whereby the ratio of these hybridizations determines the hardness of the DLC layer. In addition, the amorphous structure avoids defects and sub-nanometer roughness. All relevant properties of the DLC coating can be adjusted with the deposition parameters. As DLC coating techniques magnetron sputtering, ion beam deposition or plasma enhanced chemical vapor deposition can be used.

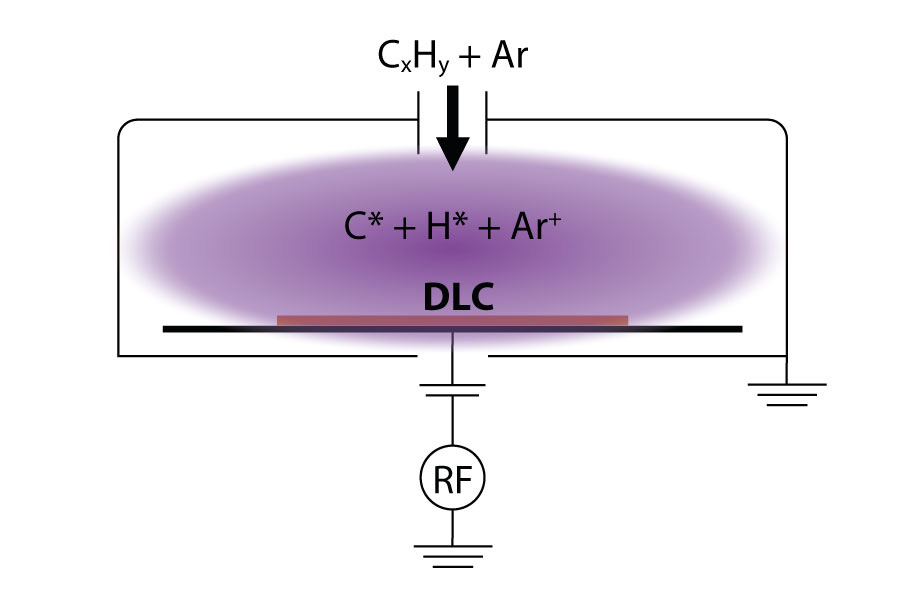

The scia Cube 300 deposits DLC films by PECVD. A 13.56 MHz RF-Power is applied to an electrode under the substrate (see Fig 4). By using hydrocarbon gases e.g. C2H2 as precursors, the molecule dissociates into reactive species:

CxHy ↔ xC* + yH*

These species can be neutrals or ions and deliver enough energy for a DLC formation on the substrate. Depending on plasma density, ion energy, hydrocarbon gas, and additional argon, DLC properties like hardness (sp2/sp3 ratio) can be tuned precisely (see Fig. 5).

Reach out

Please contact us for further information.

Related Information

Related Product - scia Cube 300

- PECVD enables the deposition of DLC layers with less than 1.5 % uniformity variation

- DLC properties are precisely adjustable by changing process conditions