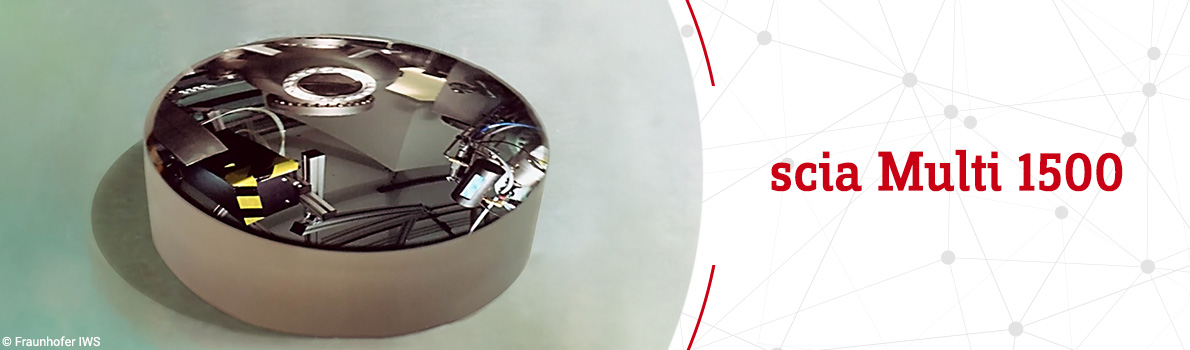

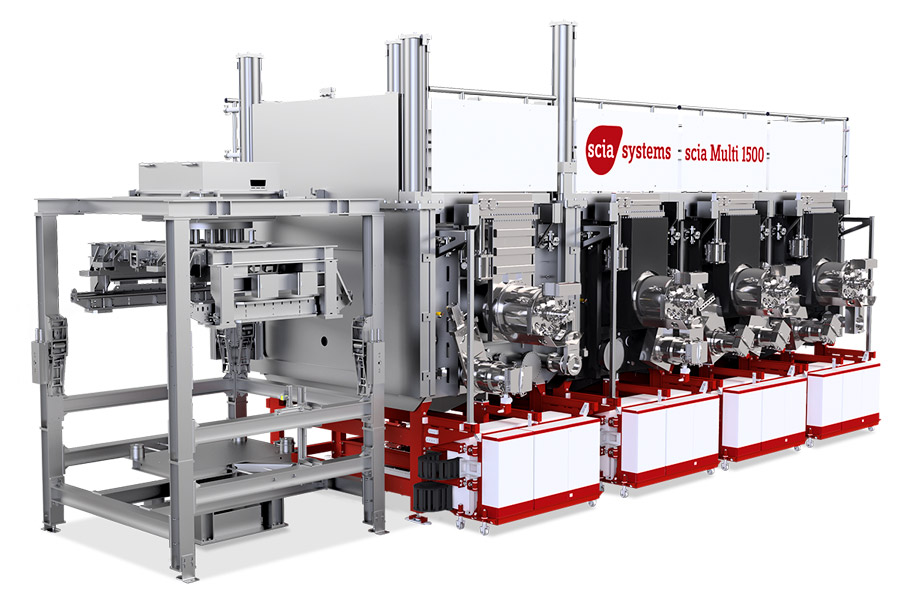

Substrate size (up to) | 1500 mm dia., 850 kg |

Sputter source | 4 rectangular magnetrons (1200 mm x 90 mm) per chamber, ion beam source possible |

Sputter modes | DC in cw or pulsed mode (6 kW) and/or |

Base pressure | < 2 x 10-8 mbar |

System dimension (W x D x H) | 11.00 m x 4.20 m x 5.00 m, for 1 process chamber (without electrical rack and pumps) |

Configuration | Inline system with multiple coating chambers and 2 buffer chambers, single substrate load lock, optional loading and balancing stage |

Software interface | OPC |

Multilayer Coatings for Large Substrates up to 1500 mm in dia.

The scia Multi 1500 is designed for periodic multilayer coatings on curved substrates. With its superior process performance over multiple 100 multilayer periods, high precision homogeneous or gradient films are possible. The modular chamber concept with separate process chambers, buffer chambers, and loading chambers simultaneously allows high flexibility, regarding the tool configuration, and high throughput.

Features & Benefits

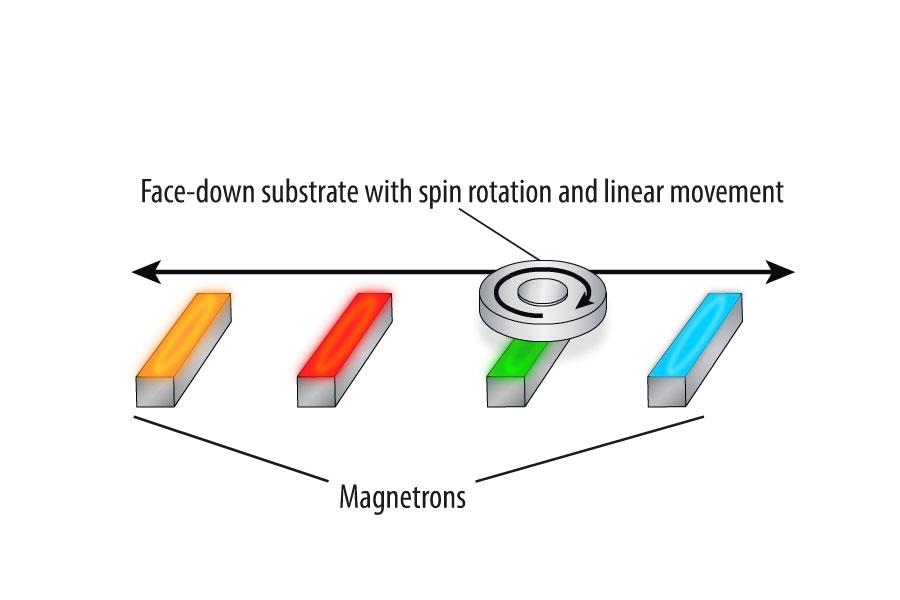

- Homogeneous or gradient films on curved substrates by synchronized linear movement and spin rotation

- Inline arrangement with multiple process and buffer chambers for complete crossing over the magnetrons

- 4 magnetrons in each process chamber

- Optional pretreatment with additional ion beam source

- Substrate face-down orientation for minimized particle load

Applications

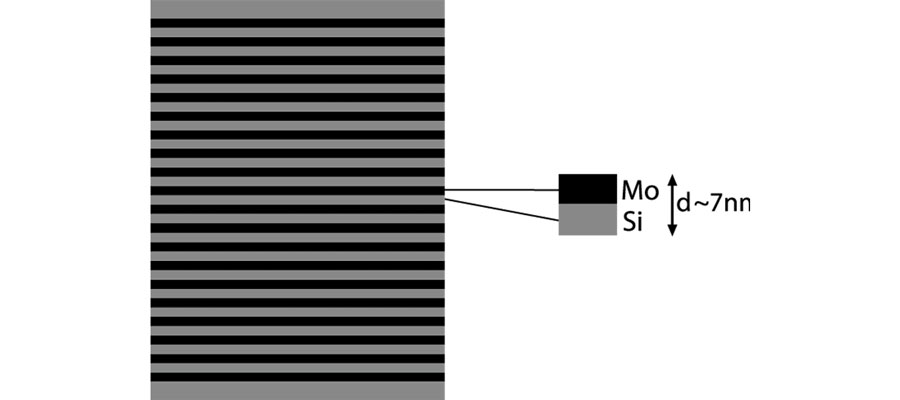

Typical multilayer stack for soft X-ray mirrors.

- Gradient multilayer coatings of mirrors for soft X-ray and anti-reflective coatings

- Multilayer stacks for X-ray mirrors for beam line and analytic applications

- Multilayer coating for UV and VIS optics

Principle

- Inline arrangement with 4 magnetrons in each process module

- Linear substrate movement across magnetrons and superimposed rotation of the substrate

Technologies

Magnetron Sputtering utilizes plasma ion bombardment on a target to deposit thin films on the substrate surface.