Substrate size (up to) | 300 mm dia. |

Sputter source | 4 rectangular magnetrons (400 mm x 90 mm) |

Sputter modes | DC in cw or pulsed mode (1 kW) and/or RF (1 kW, 13.56 MHz) |

Base pressure | < 8 x 10-8 mbar |

System dimension (W x D x H) | 3.60 m x 2.70 m x 2.30 m (without electrical rack and pumps) |

Configuration | Single chamber with cassette load lock |

Software interface | SECS II / GEM, OPC |

Multilayers by Magnetron Sputtering on 300 mm Wafers

The scia Multi 300 is designed to produce high quality multilayer coatings on wafers up to 300 mm by magnetron sputtering. The system can be equipped with up to 4 magnetrons, enabling high-precision multilayer stacks of up to 4 target materials without breaking the vacuum. The deposition of metal layers is just as possible as oxide and nitride layers. The cassette load lock with automatic substrate transfer and the system control ensures a completely automatic and recipe-controlled process.

Features & Benefits

- Excellent uniformity over 300 mm substrate area

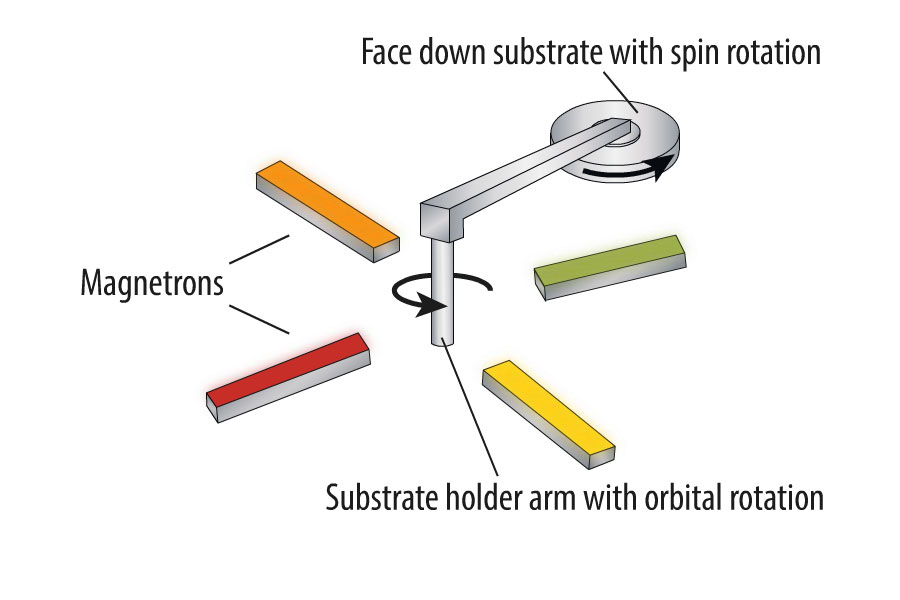

- Synchronized orbital and spin rotation for uniform multilayer films on wafers

- 4 magnetrons, each with individual gas supply and shutter unit

- Automatic cassette handling system with load lock

- Substrate face-down orientation for minimized particle load

Applications

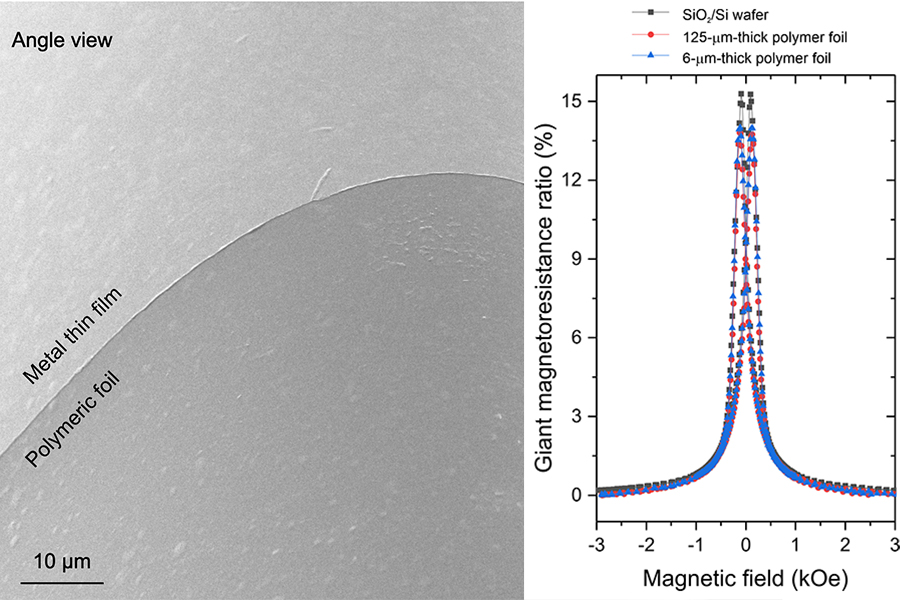

Application Example: Manufacturing of GMR sensors by HZDR: Samples prepared on different substrate materials lead to the same sensor performance.

Left Picture: View of sensor under an angle with electron microscopy | Right: Comparison of several magneto-resistance curves on different substrate types

- Gradient multilayer coatings of mirrors for soft X-ray and anti-reflective coatings

- Multilayer stacks for EUV and X-ray mirrors

- GMR and TMR based multilayer coatings

- Multilayer coating for UV and VIS optics

Principle

- Circular substrate movement across magnetrons, each orbital rotation completes one period of the stack

- Compensation of individual emission profiles of the magnetrons by precalculating the orbital rotation profiles

Technologies

Magnetron Sputtering utilizes plasma ion bombardment on a target to deposit thin films on the substrate surface.

Detailled Information

Technical Data

Process Results

PDF Download

Product Flyer scia Multi 300

Reach out

Please contact us for further information.

Product Overview

Download our brochure as PDF.