Substrate size (up to) | 300 mm dia. |

Substrate holder | Substrate rotation up to 60 rpm, includes optical thickness monitor (OTM) and test glass changer |

Ion beam sources | Sputter source: 120 mm circular RF source (RF120-e) |

Neutralizer | RF driven plasma bridge neutralizer (N-RF) |

Target holder | Target drum with 6 water-cooled targets (each up to 300 mm x 300 mm) |

Base pressure | < 5 x 10-8 mbar |

System dimension (W x D x H) | 4.60 m x 1.80 m x 2.20 m, for single chamber with double substrate load lock (without electrical rack and pumps) |

Configurations | Single chamber with double substrate load lock |

Software interfaces | SECS II / GEM, OPC |

Precision in Optical Coating

The scia Opto 300 is used for uniform coating of precision optics. With up to 6 targets for flexible multilayer deposition, even a mixing of target materials is possible. Two loading positions allow continuous and fully automatic processing of the substrates. Optical in-situ monitoring with integrated test glass changer ensures highest precision and optimized uniformity of coating.

Features & Benefits

- Variable substrate sizes up to 300 mm dia.

- Automatic loading with two loading positions for continuous processing

- Up to 6 target materials on a rotatable trum, each target up to 300 mm x 300 mm, with optimized geometry for mixed layers or smooth transition between layers

- Excellent process uniformity by substrate rotation with up to 60 rpm

- In-situ optical thickness monitor (OTM) and test glass changer

- Optimized geometry for coating with low stress

Applications

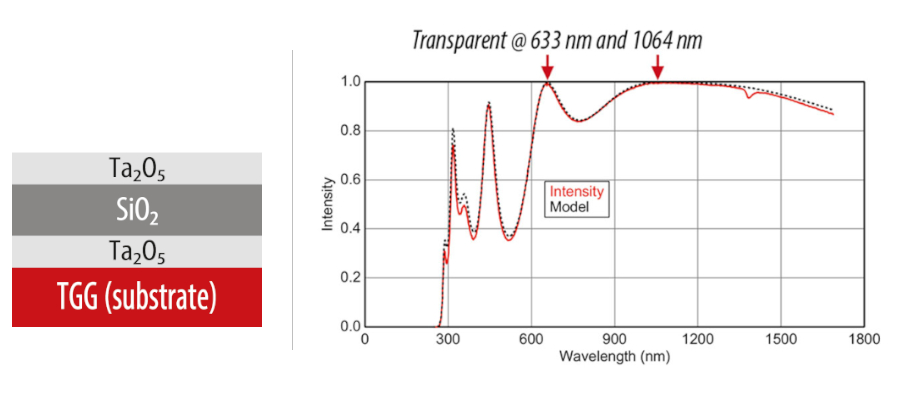

Application Example: Anti-reflex coating of a multilayer stack consisting of Ta2O5

and SiO2 on TGG, designed to be transparent for typical laser lines of 633 nm

and 1064 nm | picture left: structure of the layer stack | picture right: Transmission spectra measured with transmission mode of ellipsometer. The target values of the reflectivity could be reached.

- Dielectric mirrors (e.g. rugate filters)

- Optical coatings for high- and anti-reflective layers, bandpass and notch filters

- High laser damage threshold coatings

- Deposition of refractive index gradient layers

- In-situ preprocessing of substrates (etching, cleaning, smoothing)

- Metallic, seed and protective coatings

Principle

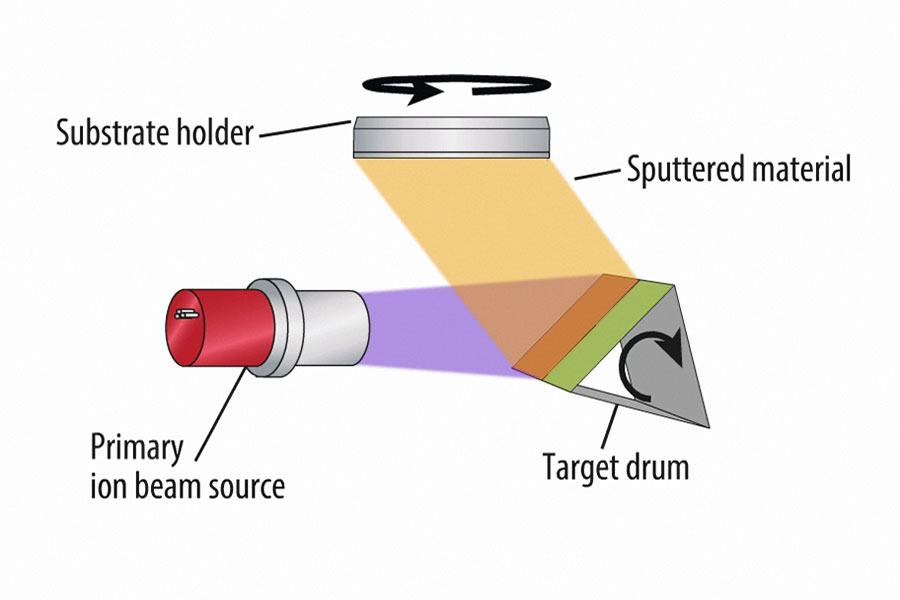

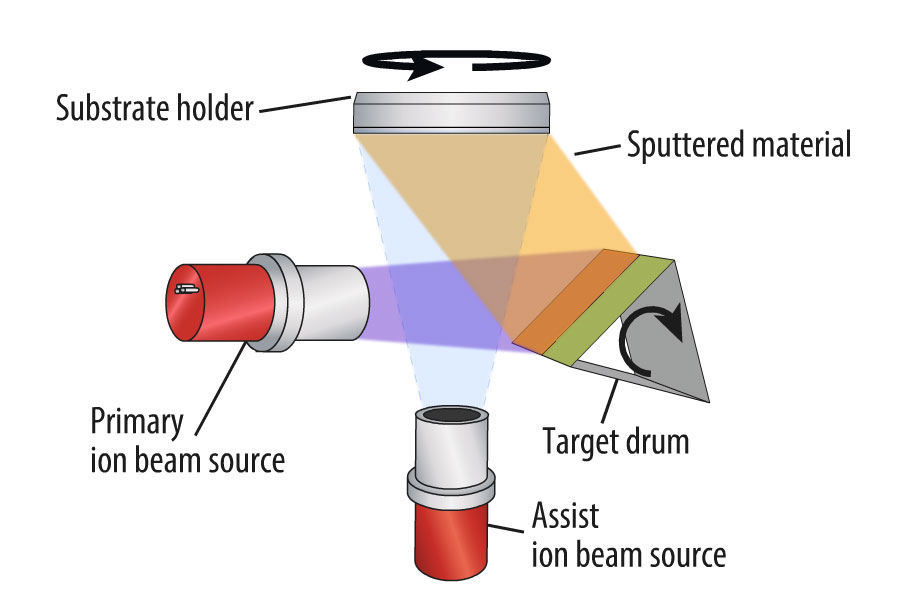

- Primary source sputters material from a target to the facedown oriented substrate

- Secondary source used for pre-cleaning the substrate and / or assist during deposition

Technologies

Ion Beam Sputtering (IBS) thereby material is sputtered from a target with an ion beam and is deposited on the substrate.

Dual Ion Beam Sputtering (DIBS) uses an additional assist ion beam source to influence the growing film.