Substrate size (up to) | 500 mm x 300 mm, 300 mm dia. for spin rotation |

Sputter source | 6 rectangular magnetrons (305 mm x 89 mm), ion source possible |

Sputter modes | DC in cw or pulsed mode (1.5 or 3 kW) and/or RF (1.5 or 3 kW, 13.56 MHz) |

Base pressure | < 5 x 10-8 mbar |

System dimension (W x D x H) | 8.10 m x 1.40 m x 2.80 m (without electrical rack and pumps) |

Configuration | Inline system with load lock and loading station at both ends |

Software interface | SECS II / GEM, OPC |

Multilayer Coatings for optical Substrates up to 500 x 300 mm

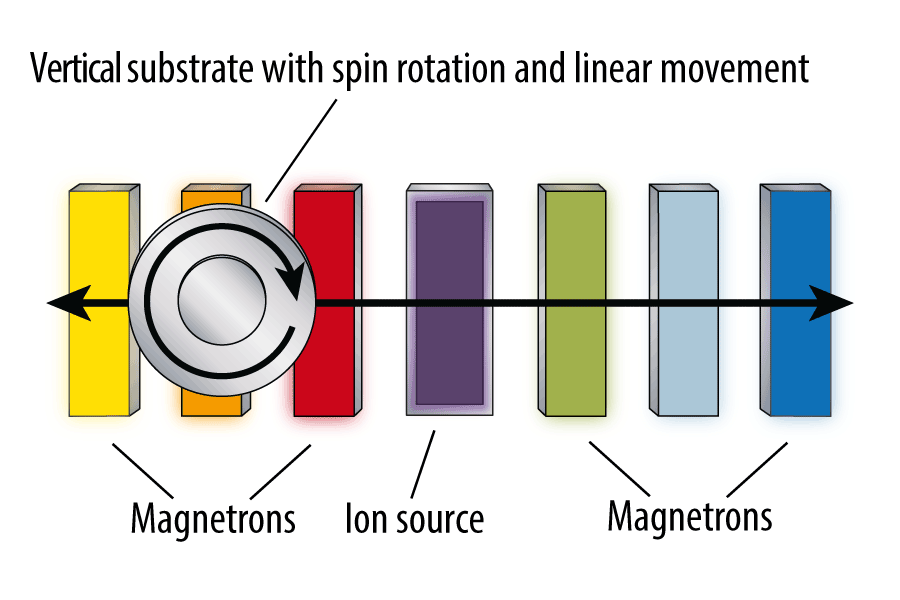

The scia Multi 500 is a magnetron sputtering system for multilayer coatings on optics at (sub-) nanometer precision. In a linear inline coating system with load locks at both ends, the vertically aligned substrate moves in front of six magnetrons with different target materials and an optional ion source. The precise position-controlled movement of the substrate enables defined gradient layers and superior deposition uniformity.

Features & Benefits

- Multilayer coating with inline arrangement of multiple process sources

- Uniform or gradient films on optical substrates by synchronized linear movement and spin rotation

- 6 linear magnetron sputter sources

- Optional surface treatment by ion source

- Vertical substrate orientation for minimized particle load

Applications

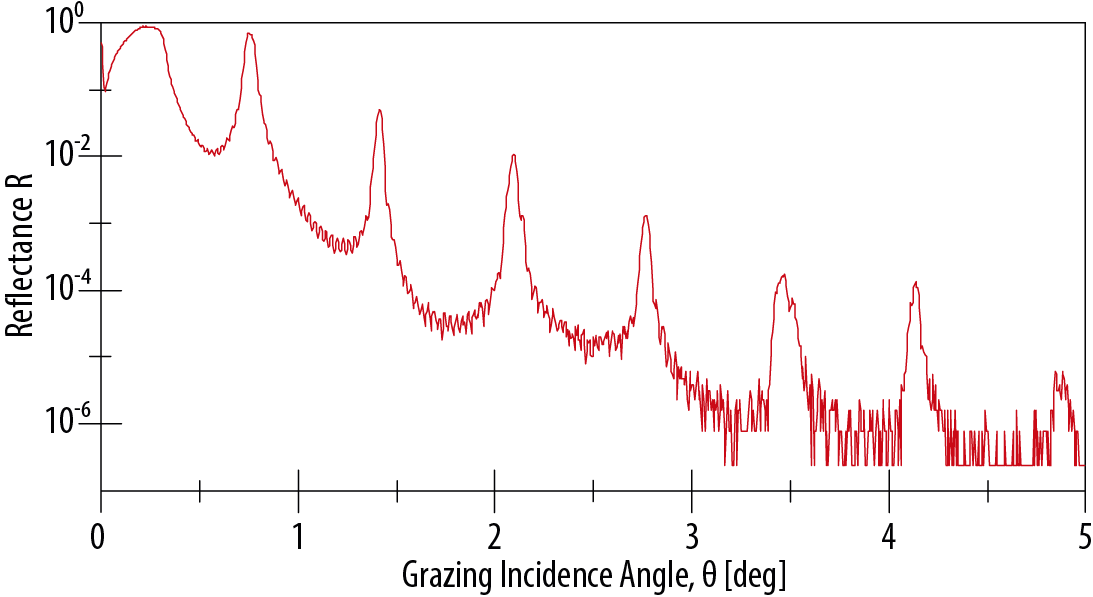

- Gradient multilayer coatings of mirrors for EUV

- Multilayer stacks for X-ray mirrors for beam line and analytic applications

Principle

- Inline arrangement with 6 magnetron sputter sources

- Linear substrate movement past magnetrons and superimposed substrate rotation

Technologies

Magnetron Sputtering utilizes plasma ion bombardment on a target to deposit thin films on the substrate surface.

Detailled Information

Technical Data

Process Results

PDF Download

Product Flyer scia Multi 500

Reach out

Please contact us for further information.

Product Overview

Download our brochure as PDF.