Substrate size (up to) | 750 mm x 750 mm |

Substrate holder | Water-cooled, RF bias |

Substrate temperature | Alternatively cryo-cooling down to -10 °C |

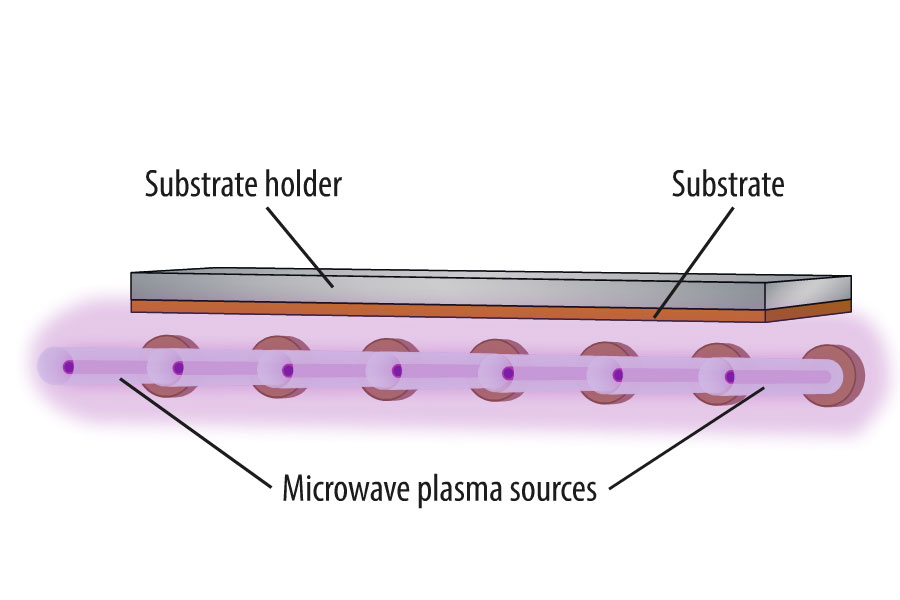

Plasma source | 7 linear microwave source (PL1300) and/or |

Power supply | MW power: max. 48 kW, RF power: max. 3 kW |

Base pressure | < 1 x 10-6 mbar |

System dimension (W x D x H) | 3.70 m x 2.50 m x 2.00 m (without electrical rack and pumps) |

Configurations | Single chamber with single substrate load lock, optional atmospheric loading system with substrate stocking |

Software interfaces | SECS II / GEM, OPC |

Large Area Coating and Etching over 750 mm x 750 mm

The scia Cube 750 is designed for large area high density plasma processes. The system enables deposition with high rates and a wide range of deposition parameters. In addition, etching processes with oxygen or halogen chemistry for high anisotropic etching and/or optimized selectivity are possible.

Features & Benefits

- Large area processing with an array of synchronized linear microwave sources

- Independent RF bias at substrate holder for energetic substrate bombardment

- Substrate face-down orientation for minimized particle load

- Substrate cooling (-10 °C)

- In-situ chamber cleaning process

- Full automation with vacuum load lock and atmosphere stocker system available

Applications

- PECVD Processes

- Deposition of dielectric films, e.g. encapsulation, barrier coatings, electric insulation (SiO2, Si3N4, …)

- Optical and scratch resistant coatings (a-C:H, DLC)

- RIE Processes

- Reactive etching and structuring of metals (Ni, Cr, Pt, …)

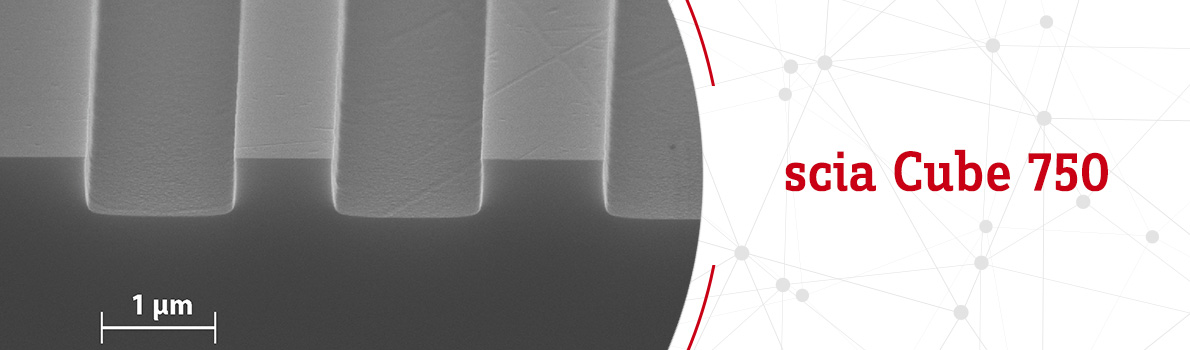

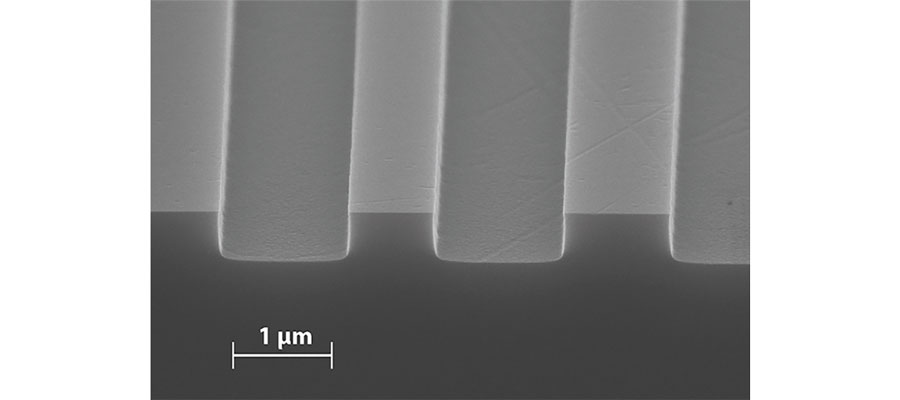

- Etching of gratings and other structures in optical materials (quartz, fused silica)

- Ashing of photoresist

Application Note

- Deposition of DLC for glass compression molds

Principle

- Plasma of reactive gases is created by microwave sources

- Enhanced ion bombardment with RF bias

Technologies

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a plasma assisted reactive process to deposit thin films from a gas state (vapor) into a solid state on a substrate.

Reactive Ion Etching (RIE) uses reactive gases and ion bombardment for physically and chemically etching of the substrate surface.