| Substrate size (up to) | 200 mm dia. |

| Substrate holder | Water-cooled, helium backside cooling contact, substrate rotation 5 to 20 rpm, tiltable in-situ from 0° to 180° in 0.1° steps, optional heating |

| E-beam evaporator | 4 to 12 pockets on a cooled crucible |

| Ion beam source (optional) | 120 mm circular RF source (RF120-e) or 218 mm circular microwave ECR source (MW218-e) |

| Neutralizer | Plasma bridge neutralizer (N-RF or N3-DC) |

| Base pressure | < 5 x 10-7 mbar |

| System dimension (W x D x H) | 1.80 m x 1.50 m x 2.40 m, for single chamber with single substrate load-lock (without electrical rack and pumps) |

| Configurations | Single chamber with single substrate load-lock or cassette handling, cluster system with up to 3 process chambers |

| Software interfaces | SECS II / GEM, OPC |

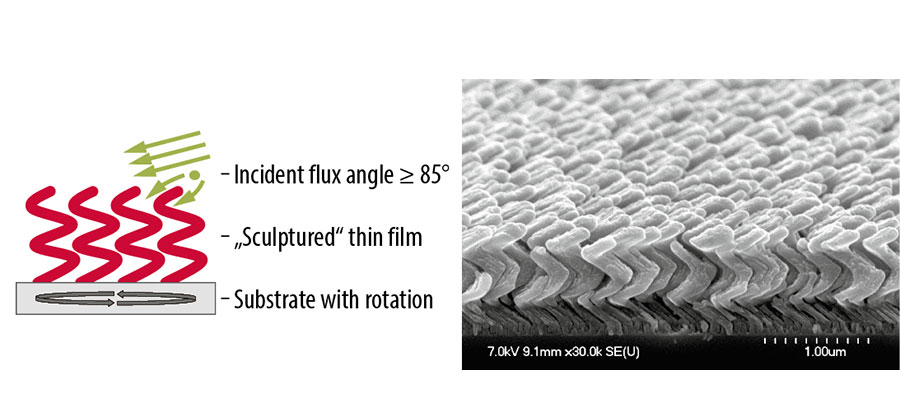

Glancing Angle Deposition for Precise Nanostructures

With the scia Eva 200 ultra-pure coatings can be deposited on up to 200 mm wafers by electron beam (e-beam) evaporation. The system enables up to 12 target materials in crucible-pockets and can be configured with single wafer load lock or with fully automated cassette handling. In addition, the system has a very small footprint and an ion beam source can be integrated for pre-cleaning.

Features & Benefits

- Substrate holder precisely tiltable and rotatable, defined angle of incidence adjustable

- High deposition rates for evaporation of high temperature materials and refractory metals

- Up to 12 evaporation materials in water-cooled multi pocket rotatable crucible

- Optional ion beam source for pre-cleaning

- Fully automatic cassette handling in variable cluster layouts including SECS/GEM communication

Single chamber with single substrate load-lock

Applications

- Glancing angle deposition (GLAD) of nano-structured thin film layers for production of photo-electrodes for efficient fuel generation

- Infrared-emitters for detection and spectroscopy for gas analyzer and smart applications

- Metallization of substrates

- Dielectric coatings

- Optical coatings

Principle

Electron Beam (E-beam) Evaporation

Current through tungsten filament causes electron emission, which accelerates to an e-beam by high voltage. A magnetic field deflects the e-beam so that it is focused into the crucible. This leads to evaporation of target material and deposition on the substrate.