Expertise in electronic manufacturing: Coating | Etching | Cleaning

scia Systems provides technologies and process equipment for various microelectronic applications:

Smart sensor technology

e.g., biotechnology sensors, lab-on-chip systems, GMR, TMR, IR sensors

High-frequency electronics

e.g., BAW, SAW

Cost-efficient power electronics

Advanced Silicon & beyond

System Integration by Advanced Electronics Packaging

e.g., multichip packages, SiPs, 3D packaging

MEMS Application Notes

Reverse Engineering of IC chip devices

Frequency Trimming of bulk acoustic wave (BAW) filters

Surface Trimming of surface acoustic wave (SAW) filters

Thickness Trimming of POI wafers for RF filters (SAW)

Film Thickness Correction of thin film read/write heads (TFH)

Temperature Compensation for surface acoustic wave wafers (TC-SAW

SENSOR Application Notes

Deposition of GMR Sensors for flexible magnetoelectronics

Etching of Magnetic Multilayers for tunnel-magneto-resistance (TMR) sensors

Etching of Lithium Tantalate for infrared (IR) sensors

One system for all your processes: scia Cluster 200

Whether you want multiple chambers dedicated to one process or want to combine our wide process know how – we have the ideal cluster-layout for you!

- Ion Beam Trimming (IBT)

- (Reactive) Ion Beam Etching (RIBE)

- (Dual) Ion Beam Deposition (DIBD)

- Magnetron Sputtering (PVD)

- Reactive Ion Etching (RIE)

- Plasma Enhanced Chemical Vapor Deposition (PEVCD)

- Atomic Layer Deposition (ALD)

- Electron Beam Evaporation (EBE)

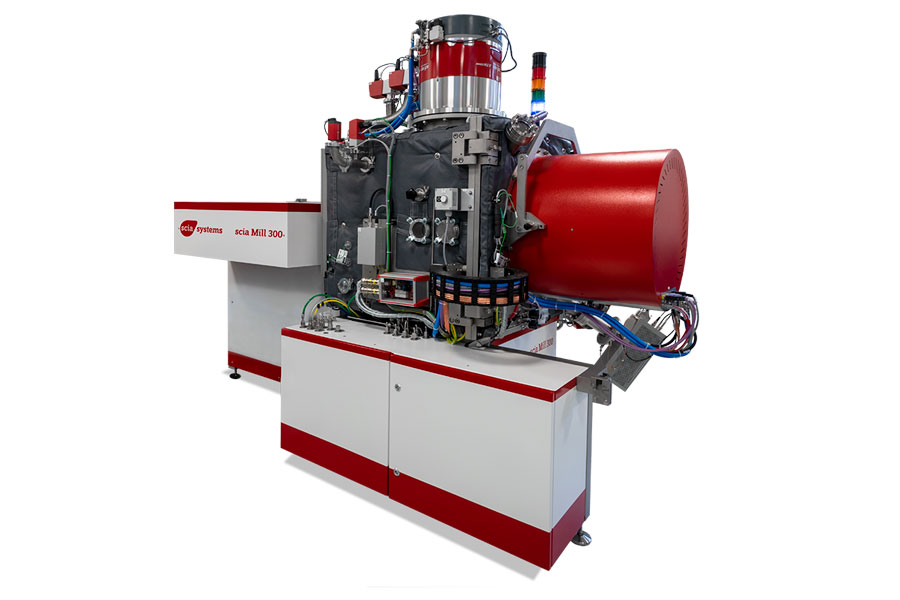

Selected systems for microelectronics production

Ask for your dedicated solution!

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Germany