Magnetron Sputtering of Silicon Dioxide

Silicon dioxide (SiO2) is an important material for manufacturing of semiconductors and microelectromechanical systems (MEMS). It is mainly used for passivation or insulation films and as dielectric layer.

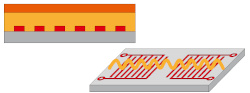

One application example is the deposition of SiO2 as temperature compensation layer for TC-SAW filter devices in mobile communication. The performance of those filters strongly depends on the quality of the deposited SiO2 layer. Therefore, a cost-effective solution for high volume production with reliable process results and high wafer throughput is needed.

Advantages of magnetron sputtering for silicon dioxide deposition

- Dense films with high homogeneity and good purity

- Excellent coating precision

- Deposition with high rates

- Low substrate temperature allows processing of materials that are very fragile and sensitive to high temperatures and rapid temperature changes

- Variation of film properties by adjustable energetic substrate bombardment

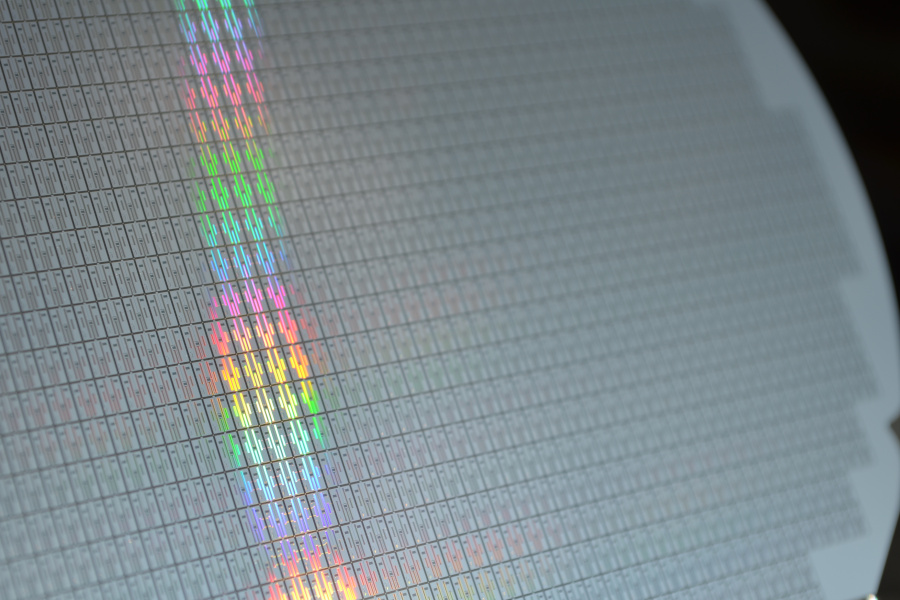

Wafer with SAW filter components

Technology

Learn more about magnetron sputtering and the different possible sputter setups in our technology overview.

Application

In our Application Note we show you, how sputter deposition of SiO2 is used for the temperature compensation of SAW filter devices.

Product

The scia Magna 200 is a coating system that is made for precise deposition of metals and/or dielectric layers on wafers up to 200 mm.

Do you want to speak to one of our experts? Contact us:

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Germany

Tel: +49 371 33561-0