Substrate size (up to) | Individual sizes loaded on carrier, carrier size up to 450 mm x 400 mm |

Ion beam source | Two 380 mm linear microwave ECR sources (LIN380-e) |

Sputter source | Two rotatable magnetrons with 680 mm length |

Throughput | 12 Carrier/h ≈ up to 500,000 blades/h |

Base pressure | < 1 x 10-6 mbar |

System dimension (W x D x H) | 6.10 m x 1.60 m x 1.95 m, for 2 process chambers (without electrical rack) |

Configurations | Inline system with several etching and coating chambers, roller track transport system, 2 load locks and 2 atmospheric stations for loading and unloading |

Software interfaces | SECS II / GEM, OPC |

Ultra-Sharp Edges for Blades

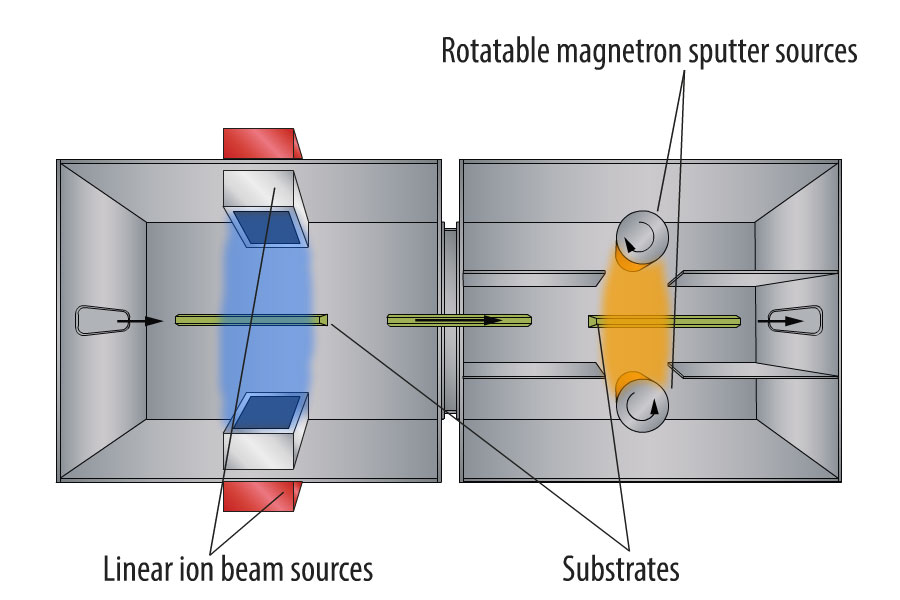

The scia Inline 400 was designed for shaping the edges of high-quality blades - using ion beam etching and magnetron sputtering. The basic configuration of the system consists of two process units: The first one is equipped with an ion beam source for deburring and pre-cleaning of the blades. In the second process chamber opposite magnetron sputter sources are installed to coat both sides of the substrates simultaneously. The inline concept with two load locks enables a fast loading and unloading procedure, which results in a very high throughput. Furthermore, the modular design allows easy upgrading with additional process chambers as well as integration into existing production lines.

Features & Benefits

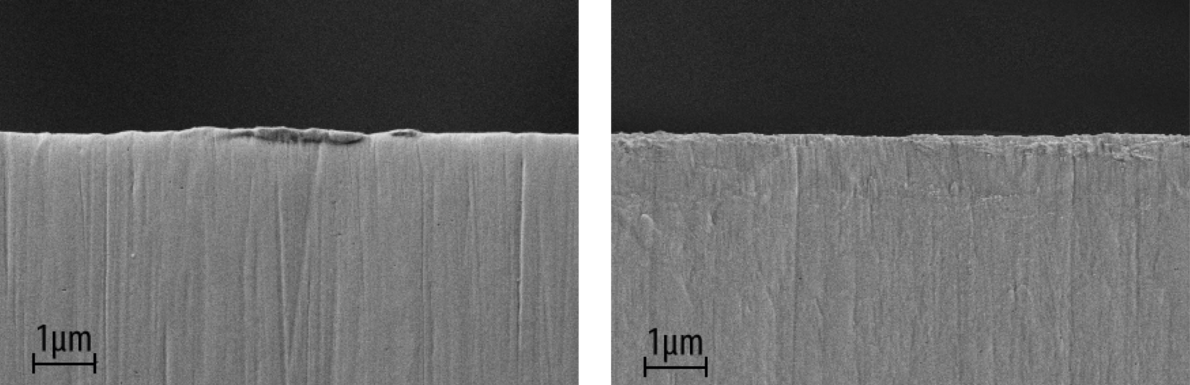

- Deburring station for ultra-sharp substrate edges

- Carrier-based handling to address various substrate dimensions

- Vertical layout enables double-sided processing for extreme high throughput in volume production

- Inline arrangement with multiple process chambers and roller track transport system

- Two load-locks for fast loading and unloading procedure, thus increased throughput

Applications

- Tip shaping of razor blades, microtome blades or sharp medical tools (syringes) for a durable coating adhesion

- Coating of adhesive and/or functional layers on razor blades and microtome blades

Principle

- Inline arrangement with linear substrate movement

- Chamber one with ion beam sources for pre-cleaning

- Chamber two with magnetrons for double-sided coating of the substrates

Technologies

Ion Beam Etching (IBE) / Ion Beam Milling (IBM)

uses a collimated beam of inert gas ions for material removal.

Magnetron Sputtering

utilizes plasma ion bombardment on a target to deposit thin films on the substrate surface.