Video presentation: How to structure your optics with ion beam etching

For optics processing, scia Systems offers several technologies and equipment, for example ion beam etching, ion beam deposition and magnetron sputtering. In this video, the focus of our Technical Sales Manager Philipp Böttger is on ion beam etching and how this technology can help you to structure your optics.

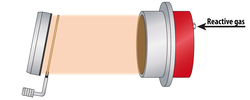

By introducing reactive gases into the etching process, called Reactive Ion Beam Etching, it is possible to control the selectivity of different surface materials or even to enhance the etch rate. This opens up different application possibilities, two of which are presented by Philipp Böttger:

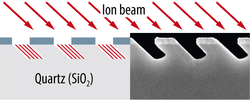

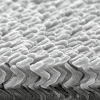

The first is proportional or non-proportional pattern transfer from a resist mask using reactive ion beam etching. The second application example is the production of surface relief gratings which are used as input or output couplers in optical waveguides for augmented reality devices.

Here you can see the presentation.

Technology

Learn more about Reactive Ion Beam Etching (RIBE) and Chemically Assisted Ion Beam Etching (CAIBE) in our technology overview.

Application

In our Application Note, we show you how to use Reactive Ion Beam Etching to process surface relief gratings for AR- & MR-devices.

Product

The scia Mill 200 is a fully production proven system with reactive gas compatibility in RIBE and CAIBE processing, including fluorine / chlorine.

Do you want to speak to one of our experts? Contact us:

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Germany

Tel: +49 371 33561-561