Substrate size (up to) | 200 mm dia. |

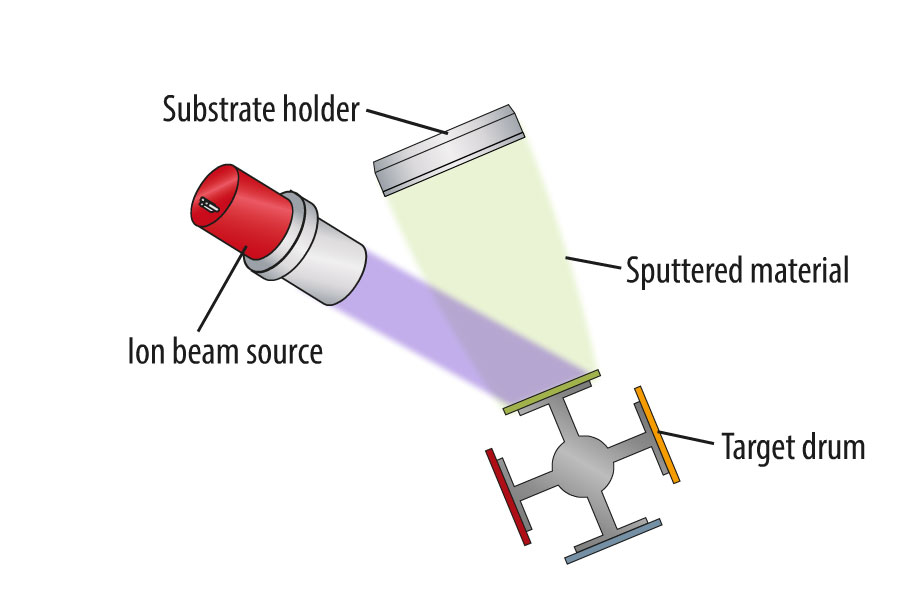

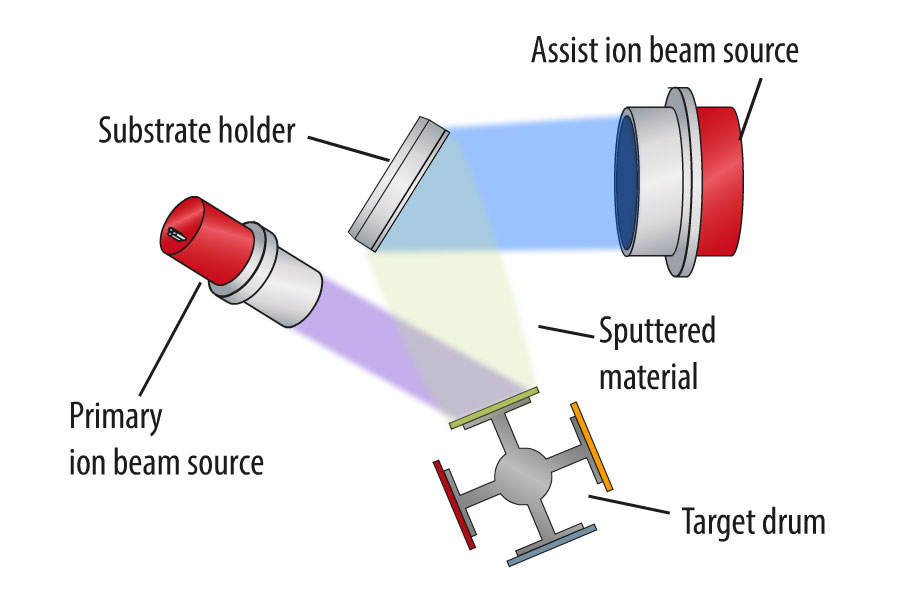

Substrate holder | Water-cooled, helium backside cooling contact, substrate rotation 5 to 20 rpm, tiltable in-situ from 0° to 170° in 0.1° steps |

Ion beam sources | Sputter source: 120 mm circular RF source (RF120-e) |

Neutralizer | Filament driven (N-DC) or RF driven (N-RF) plasma bridge neutralizer |

Target holder | Target drum with tiltable and water-cooled targets, up to 5 (each max. 220 mm dia.) or up to 4 (each max. 300 mm dia.) |

Base pressure | < 5 x 10-7 mbar |

System dimension (W x D x H) | 3.10 m x 1.70 m x 2.40 m, for single chamber with cassette handling (without electrical rack and pumps) |

Configurations | Single chamber with single substrate load lock or cassette handling, cluster system with cassette handling |

Software interfaces | SECS II / GEM, OPC |