Latest Company News

Runxin MEMS Technologies increases output yield of produced filters by ion beam trimming

In March 2022, Runxin MEMS Technologies Co., Ltd. was established in the Microelectronics Science Park as a new industrial base for MEMS production in the Nanchang High tech Zone. Co-founder of Runxin MEMS Technologies is CSMC, a big Semi company that already uses multiple scia Trim 200 systems and a scia Mill 200 system. Now they decided to open a company solely dedicated to MEMS products. The main purpose of this new factory will be designing and manufacturing of sensors for consumer electronics, automotive, industrial and pharmaceutical applications.

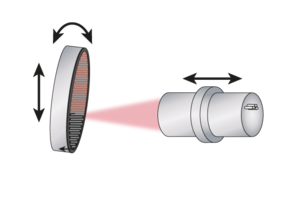

In order to encounter the rapid and high-quality development of these industries, Runxin expands its capacities, drawing on CSMC's good experience by purchasing a scia Trim 200. With this ion beam trimming system especially the production of BAW and SAW filters will be more efficient. By layer thickness trimming, the yield of functional components can be increased up to 90%.

But that's just the beginning: Since ion beam technology can be used to process all solid materials, many other applications are also possible in the future. The scia Trim 200 is suitable for processing all wafer types and sizes up to 200 mm. For even higher throughput, Runxin has chosen a double chamber configuration with 2 cassette load locks.

The scia Trim 200 will be delivered this year and installed in Nanchang City, Jiangxi Province.

We appreciate the trust placed in us by Runxin MEMS Technologies Co. Ltd. and wish them all the best for their research and production in the MEMS industry. A special Thank You goes to our partners from WESi for the good cooperation in this project.

- More information about the system and the possible applications you will find here: scia Trim 200.

- Learn more about the technology of ion beam trimming.

- Any questions left? Our team will be happy to help you. Contact us!