Participation on joint research project - NanoTools

Development of coated micro cutting tools based on nano wear-protection layers

Objective

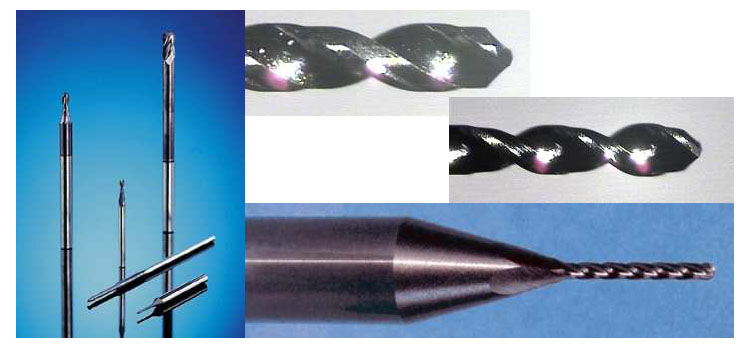

So far, many industries, such as medical, automotive, and aerospace engineering, as well as tool-making, mold making, and microelectronics, use uncoated, extremely sharpened tools for special machining processes. The reason is the required minimum cutting edge rounding, which is essential for a high workpiece quality (low surface roughness, high dimensional accuracy, burr-free, and delamination-free processing of composites).

Disadvantageous, however, are the high tool costs, caused by the short tool lifetime. Extremely thin and wear-resistant hard coatings are needed to increase the capability of machining micro and finishing tools as well as to develop further potentials for cost savings as well as quality improvements.

A promising approach is provided by ALD coatings (ALD - atomic layer deposition) and ion beam coatings (DIBD – dual ion beam deposition). So far, these processes were predominantly used for the deposition of functional films on microelectronic and photovoltaic devices. The objective of the joint project is to provide a scientific-technical base for the reliable industrial use of ALD and ion beam technique, in comparison to PVD coatings, as well as to define their field of application. The R&D task is to obtain knowledge about manufacturing and application of novel coated tools. This is to be accomplished by a collaboration between industrial companies and R&D institutes.

Planned approach

The pursued approach is based on theoretical and experimental studies on:

- Tool concept regarding base body structure, ductility and geometry

- Machine technology and technology optimization for high-performance tools

- Applied manufacturing of microgeometry and topography of cutting edges and flutes

- Layer material and structure

- Operating conditions for ALD technology compared to ion beam technology

- Applied layout criteria of tool design and dimensioning

- Test and evaluation strategies as well as quality control during the process

- Qualitative monitoring of coated tools and control of functional relevant characteristics

- Criteria (technical and economic) for plant development of the preferred option

Funded by